当前位置:网站首页>Question bank of basic principles of steel structure

Question bank of basic principles of steel structure

2022-07-23 12:29:00 【Kyle942】

Question bank of basic principles of steel structure choice question

edit

Add picture comments , No more than 140 word ( Optional )

2. The grouping of steel in the specification is based on steel ( D ) affirmatory . A: Steel grade ; B: Steel grade ; C: The size of the cross wearing area ; D: Thickness and diameter 3. The yield condition of steel under complex stress state is determined by (D) Equal to the yield point in uniaxial tension . A: Maximum principal tensile stress ; B: Maximum shear stress ; C: Maximum principal compressive stress ; D: Ultimate strength converted stress 4. Brittle failure occurred in a member , After inspection, the following problems were found in the component when it was destroyed , But it is certain that (D) There is no direct impact on the damage . A: The yield point of steel is too low ; B: The load of the component increases too fast ; C: There is cold work hardening ; D: The component has stress concentration caused by structural reasons 5. The more serious the stress concentration is , The steel becomes more brittle , This is because (B) A: Stress concentration reduces the yield point of the material ; B: Stress concentration produces a stress field of the same number , Restrict plastic deformation ; C: The stress at the stress concentration is higher than the average stress ; D: Stress concentration reduces the tensile strength of steel 6. An element seriously reduces the plasticity of steel 、 toughness , Especially when the temperature is low, it makes the steel brittle . The element is (B). A: sulfur ; B: phosphorus ; C: carbon ; D: manganese 7. The stress state most prone to brittle failure is (B). A: Uniaxial compressive stress state ; B: Three dimensional tensile stress state ; C: The stress state of two-way tension and compression ; D: Uniaxial tensile stress state 8. When checking fatigue , The design stress amplitude of the calculation part shall be in accordance with (A) A: Standard load calculation ; B: Design load calculation ; C: Standard load calculation considering dynamic coefficient ; D: Design load calculation considering dynamic coefficient

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

10. The batten in the lattice axial compression bar should be in accordance with (B) Calculation . A. Axial tension member B. Axial compression members C. Flexural member D. Eccentrically loaded member 11.《 Code for design of steel structures 》(GB50017-2003) in , The column curve to determine the overall stability coefficient of axial compression members is (D) strip .

A.1 B. 2 C. 3 D. 4 12. The form of instability of uniaxial symmetric axial compression members around the axis of symmetry is (B), The converted slenderness ratio considering torsion effect is adopted in the calculation . A. Bending instability B. Torsional instability C. Bending and torsion instability D. It's the same as around the asymmetric axis 13. When calculating the overall stability of lattice axial compression bar around the virtual axis , The reason for using the converted slenderness ratio is (B). A. The effect of torsion B. Effect of shear deformation C. Effect of local instability D. Effect of additional bending moment 14. Which of the following factors is related to the calculated length of axial force bearing members ?(B) A. Section shape of member B. End support of member C. Stress condition of member D. Section stiffness of member 15. The principle of determining the width thickness ratio limit of web and flange of Web column under axial compaction is (A) A. Equal stability principle B. Edge yield criterion C. Equal strength principle D. Equal stiffness principle 16. When calculating the strength and overall stability of axial compression members , How to take the cross-sectional area (B). A. Gross cross-sectional area for strength , Net sectional area for stabilization B. Net sectional area for strength , Stable gross cross-sectional area C. All use gross sectional area D. Use net sectional area

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

20. In the last question , The calculated value of the overall stability stress of the member 、 Allowable width thickness ratio of flange plate 、 The allowable height thickness ratio of the web is (B). A.149Mpa , 13, 40 B. 170Mpa, 15.725, 53.625 C.224.6Mpa, 18.98, 69.91 D.577Mpa, 20, 75 Short answer :1 What are the mechanical properties of structural steel ? (1) Strength (2) plasticity (3) Cold bending performance (4) Impact toughness (5) Solderability (6) Durability 2 What are the factors that affect the mechanical properties of structural steel ? (1)、 Chemical composition (2)、 Metallurgical defects (3)、 Steel hardens (4)、 The effect of temperature (5)、 Stress concentration (6)、 Repeated load action . 3 There are several basic forms of steel failure ? Try to describe their failure characteristics and microscopic essence (1) Plastic failure , features : The destruction took a long time , Large deformation of material , The broken fracture is uneven , It's dark , Due to the mutual sliding of crystals under shear, they are fibrous ; Microscopic essence : Ferrite grains are sheared . (2) Brittle failure , features : Destruction happens suddenly 、 Without warning , Material deformation is small , The broken fracture is even , Grains tend to fracture on one surface and appear as glossy grains ; Microscopic essence : Ferrite grains are broken . 4 Please briefly describe the conditions of fatigue failure 、 Fatigue fracture process ? Steel under repeated load 、“ Low stress state ” Destruction under ; Fracture process : Micro crack formation ( It has 、 High stress zone formation )、 The crack grows slowly ( Crack propagation , Serious stress concentration )、 Finally, it breaks quickly ( Too much weakening of the section , Brittle fracture occurs . 5 What factors should be considered when selecting steel ? (1) Type and importance of structure or member .(2) Load nature .(3) Connection method .(4) The working conditions of the structure (5) Structural form and steel thickness (6) Mechanical properties of the structure 6 An example is given to illustrate the causes of stress concentration in the section of steel members , An example is given to illustrate the structural measures to reduce the degree of stress concentration in the project ? reason : The surface of the component is uneven , There are grooves 、 The gap , When the thickness changes suddenly , Uneven stress , The force line turns zigzag . explain : Minimize stress concentration through structural measures . 6 Classify from function , What are the basic types of connections ? (1) Stressed connection (2) Connective connection (3) Supporting connection 7 There are two basic types of welds — Butt groove weld and fillet weld , Both are under construction 、 Stress 、 What are the characteristics of the scope of application ? (1) butt weld , During construction, it must be fully welded , The weld material will be welded “ melting ” Become one , For members with larger thickness , Before welding, the crater shall be sloped , To ensure full penetration . advantage : Save steel 、 Low stress concentration , High weld quality , Good fatigue resistance ; shortcoming : High dimensional accuracy and welding process requirements for weldments . (2) Fillet welds : Penetration is not required , The weld material will be stuck together by the weldment . advantage , Weldment size 、 Low welding process requirements , Strong adaptability , Proportion in weld 80%; shortcoming , High stress concentration , Poor stress conditions ; Low fatigue strength , Cannot bear dynamic load directly . 8 Butt weld is required for butt joint connection , Fillet weld shall be adopted for the connection of fillet joint , Is that right ? incorrect , Because the same type of joint can be realized by two kinds of welds . 9 hf and lw Phase at the same time , The bearing capacity of the front fillet weld is higher than that of the side fillet weld on the crane beam ? Yes , The side fillet weld mainly bears shear , The strength is relatively low , Good plasticity , Bending occurs when passing through the weld due to external force , Therefore, the shear stress is unevenly distributed along the length of the weld , Big at both ends and small in the middle . 10 Why are there restrictions on the maximum and minimum values of the weld leg size of the diagonal weld ? What are the requirements for the length of side fillet welds ? Why? ? Calculation length limit of side weld :8hf ≤lw1 ≤60hf ( static load 、 Indirect dynamic load ) 8hf ≤lw1 ≤40hf ( Live load ) Too short : Local heating is serious , And the distance between the take-off and landing craters is too close , Plus possible defects , Unstable welding . Too long : Both ends are destroyed first , Intermediate welds are not functioning . 11 Briefly describe the essence of welding residual stress , What is its biggest distribution characteristic ? The essence , When welding , The thermal expansion of weld and heat affected zone is plastically compressed due to the constraint of surrounding materials . Distribution characteristics :(1) The integral of residual stress in any direction on any section is zero ,(2) On the vertical weld section , Residual stress in weld section and heat affected zone , There is compressive stress in the restraint area .(3) On the section parallel to the weld , Welding residual stress is related to welding sequence , The distribution is complex . 12 Draw the welding H Distribution diagram of welding residual stress of V-section and welded box section .

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

13 In fillet weld , What is end weld ? What is a side weld ? What is the difference between the stress properties of the two failure sections ? Side weld : Weld parallel to the stress direction ; characteristic : Under the action of shear stress , Good plasticity , The strength is low , About... Of the end weld strength 75%. Big at both ends 、 The middle is small , The longer the weld , The more uneven the distribution . End weld : Weld perpendicular to the stress direction ; characteristic : The stress state is complex , That is, non shear stress , Nor normal stress , It is a kind of stress between the two . Because it contains normal stress components , The strength of end weld is higher than that of side weld , But relatively crisp 14 Specifications stipulated : The calculated length of the side weld shall not be greater than a certain multiple of the weld leg size , What is the reason why ? The specification also stipulates the minimum size of the weld , What is the reason why ? Calculation length limit of side weld :8hf ≤lw1 ≤60hf ( static load 、 Indirect dynamic load ) 8hf ≤lw1 ≤40hf ( Live load ) Too short : Local heating is serious , And the distance between the take-off and landing craters is too close , Plus possible defects , Unstable welding . Too long : Both ends are destroyed first , Intermediate welds are not functioning . 15 Specifications prohibit 3 Two mutually perpendicular welds intersect , Why? . answer : Due to the three-dimensional stress in the weld , Plastic deformation is hindered , At low temperature, cracks are easy to occur and develop , Accelerate the brittle failure of components . 16 for 3~5 An example is given to illustrate the structural measures to reduce stress concentration in welding design . answer : Design measures : The arrangement of welding position should be reasonable 、 Weld size should be appropriate 、 The number of welds should be less 、 Try to avoid vertical crossing of two or three welds 、 Try to avoid shrinkage stress in the thickness direction of base metal ; Measures for construction technology : Adopt reasonable welding sequence 、 Adopt anti deformation 、 For small size weldments , Preheat before welding , Tempering and heating after welding to 600℃ about , Then slowly cool , It can eliminate welding stress and welding deformation , The rigid fixing method can also be used to fix the components to limit the welding deformation , But it increases the welding residual stress . 17 Briefly describe the meaning of medium strength method and internal force method in connection design . 18 Why arc striking plate is used in butt welding ? How to consider when arc striking plate is not used ? In which cases the butt weld does not need to be calculated ? answer : Craters and other defects often appear at the arc starting and extinguishing points of welds , These defects have a great impact on the bearing capacity , Therefore, arc striking plate and lead-out plate should be set generally during welding , Cut him off after welding ; Arc striking shall be set for the structure under static load ( Out ) When the board is in trouble , allow No arc striking ( Out ) plate , here , The calculated length of the weld can be equal to the actual length minus 2t,t Is the thickness of thinner weldment ; Experiments show that welding defects have little effect on butt welds under compression and shear , Therefore, it can be considered that the strength of the butt weld under compression and shear is equal to that of the base metal , But the tensile butt weld is very sensitive to defects , Because the strength of the weld joint and the base metal in the first and second level inspection are equal , Therefore, only the welds inspected at Level 3 need to be checked for tensile strength . 19 How to grade weld quality inspection ? answer :《 Code for acceptance of construction quality of steel structure engineering 》 According to the inspection method and quality requirements, the welds are divided into one level 、 Two and three . Class III welds only require visual inspection of all welds and meet class III quality standards ; Class A 、 In addition to visual inspection, secondary welds , It also requires a certain amount of ultrasonic inspection and meets the quality standards of the corresponding level . Visual inspection of weld quality, inspection of appearance defects and geometric dimensions , Internal non-destructive inspection to check internal defects .

20 Try to judge the most dangerous point of bracket butt weld shown in the figure below

edit

Add picture comments , No more than 140 word ( Optional )

The danger is 2 spot 21 Common bolts 、 Friction type high strength bolt 、 What is the force transmission mechanism of shear type connection of pressure bearing high-strength bolts ? answer ;

edit

Add picture comments , No more than 140 word ( Optional )

1、 The elastic stage of frictional force transmission (0-1 paragraph ),2、 Slip stage (1-2 paragraph ),3、 The elastic stage of direct force transmission of the bolt rod (2-3 paragraph ),4、 Elastoplastic stage (3-4 paragraph ) 22 Under what conditions does the design value of single bolt shear capacity of ordinary bolt group need to be reduced ? Why reduce ? How to reduce ?( It is required to draw the joint structure and reduction curve ). answer : When L〉15d When the connecting work enters the elastoplastic stage, the inner parts of each screw are also uneven , The end screw first reaches the ultimate strength and breaks , Then it is destroyed from the outside to the inside .

edit

Add picture comments , No more than 140 word ( Optional )

23 How to distinguish the large bolts in tension when the ordinary bolt group is subjected to eccentric force 、 Small eccentricity ? answer : The external force on the screw group is not on the center line of the screw group , Is eccentric force . In the first case, all screws are under tension with small eccentricity , There is a separation trend between the end plate and the column wing , And bending moment M Then the centroid of bolt group O The horizontal axis at is the triangular stress distribution of the neutral axis , Pull the upper screw , The lower screw is under pressure , After superposition, all screws are under tension . Large eccentric tension in the second case , When eccentricity e large , namely e〉 Under the stress diagram, there is a compression zone at the bottom of the end plate

edit

Add picture comments , No more than 140 word ( Optional )

24 Why should we control the pretension of high-strength bolts , How to determine its design value ? answer :1、 The tensile strength of the bolt itself is limited , If the prestress is too large, the bolt itself will deform .2、 Under high prestress, the bolt will creep and cause stress drop , If excessive prestress calculation is adopted , It can lead to insufficient stress after prestress reduction , The component actually fails . Its design value is considered :1、 Material inhomogeneity reduction factor .2、 To prevent the reduction coefficient of screw damage caused by overlength tension during construction .3、 Consider tightening the nut , Shear force produced on the bolt stem .4、 Additional safety factor 25 The bolt group is under the action of torque , Under what assumptions is the internal force of the bolt with the largest force in the elastic stress stage obtained ? answer :1、 Ordinary bolt groups assume that the connecting plate is absolutely rigid , Bolts are elastic ; The neutral axis of the bolt group is located at the centroid of the lowest row of bolts , The tension of each bolt is proportional to the distance between the bolt and the shaft 2、 Because the tensile bearing capacity of high-strength bolts is generally less than its pre tensile stress , Therefore, under the action of bending moment , The contact surface of the connecting plate is always in close contact , Good elasticity , It can be considered as a whole , Therefore, it is assumed that the neutral axis of the connection coincides with the axial mandrel of the bolt , The outermost bolt bears the greatest force , Under the action of eccentric force 26 Friction type high-strength bolt itself does not have the problem of fatigue failure , What is the reason why ? answer : Because the internal force is transmitted by friction between high-strength friction bolts , The failure criterion is to overcome friction , Its friction is greater than the external force on the bolt , The bolt will not slip , There is no cyclic stress , There will be no fatigue damage , Once slip occurs, the high-strength friction bolt will be destroyed .. 27 When connecting the axial pull rod with pressure bearing high-strength bolts , Whether it can bear dynamic load directly ? Why? ? answer : It cannot bear dynamic load directly , Pressure bearing high-strength bolts allow sliding between connected parts , After sliding, the shear force is transmitted by the bolt dry shear resistance and bearing diameter ,1 His allowable external force may be greater than the friction , Generate relative slip , There is cyclic stress under dynamic load , There may be fatigue failure 28 How to express the performance grade of bolts ? answer : Use minimum tensile strength 、 Flexure ratio 29 Explain the concept : The overall stability of the compression bar 、 Local stability of compression bar 、 The converted slenderness ratio of lattice compression bar . answer :1、 The overall stability of the pressure bar is when the pressure bar reaches a certain value under the central pressure , The compression member may be suddenly bent and damaged , That is, the pressure bar is unstable .2、 Axial compression members are composed of some plates , Generally, the thickness of the plate is smaller than the width of the plate , The clad plate and flange parts are easy to deform in advance , Local instability occurs , Because some plates quit work after yielding , Reduce the effective section of the member , It will accelerate the overall loss of stability of the construction , Local instability 30 Why limit the slenderness ratio of the tie rod to ensure its stiffness ? answer : The main consideration is to avoid too much flexibility of components , It produces excessive deflection under its own gravity and bending during transportation and installation , And large vibration under dynamic load , Or the ultimate bearing capacity of the member decreases significantly , At the same time, the deflection caused by initial bending and self weight will also have an adverse impact on the overall stability of the component .” 31 What are the differences between the actual axial compression bar and the ideal axial compression bar ? answer : The so-called ideal axial compression bar is to assume that the bar is completely straight 、 The load acts along the bar shaped mandrel , The member has no initial stress before being loaded , There are no defects such as initial bending and initial eccentricity , The section is uniform along the member . If this kind of member is unstable, Hakka buckling is divided into bending buckling 、 Torsional buckling 、 Flexural torsional buckling ; In practice, various initial defects often exist at the same time , There are changes from the beginning until instability , But from the point of view of probability and statistics , The possibility of all kinds of defects reaching the most unfavorable at the same time is very small . 32 What are the main factors that affect the overall stability and bearing capacity of the compression bar ? answer : And the length of the member , The boundary conditions , External load , The strength of the material , Slenderness ratio , Calculate the length , The actual length and the constraint relationship at both ends of the component , The radius of gyration and the section size of the component are related . 33 What is the checking principle of the local stability bearing capacity of the compression bar ? answer : For ordinary steel structures , The general requirement is that the principle of equal stability and local instability are not earlier than the overall instability , That is, the critical stress of the plate is not less than the critical stress of the member , Ensure that the local instability is not earlier than the overall instability , The width thickness ratio limit of the plate shall meet the corresponding conditions . 34 Why does the lattice axial compression bar use the converted slenderness ratio to check the overall stability around the virtual axis ?( A little ) answer : For lattice compression bar , When it loses stability around the crankshaft , Because the limb parts are not continuous plates, but are connected with battens or battens at certain intervals . The shear deformation of the component is large , The additional deflection effect caused by shear cannot be ignored , In the design of lattice compression bar , Calculation of virtual axis instability , The influence of shear deformation is often considered by increasing the slenderness ratio , The increased slenderness ratio is called the converted slenderness ratio . 35 The stability factor of axially compressed members j Why should it be divided into four categories according to the section form and the corresponding axis ? Is the section category of the same section about two centroid axes necessarily the same ? answer : The critical stress given by Chinese code σcr, According to the maximum strength criterion , And determined by numerical analysis . Due to various defects on different sections 、 Different axes of symmetry have different effects , therefore σcr-λ curve ( Column curve ), It is distributed in a fairly wide band , In order to reduce the error and simplify the calculation , Specifications are based on tests , Four curves are given ( Four types of sections ), And the stability coefficient is introduced . Coincidence probability meets both reliability and economic requirements , Not necessarily the same , If the slenderness ratio of the same section member is different, the section category is not necessarily the same . 36 When the overall stability of axial compression members does not meet the requirements , If the cross-sectional area is not increased , Whether other measures can be taken to improve its stable bearing capacity answer : The following measures can be taken : Strengthening boundary conditions , Add lateral restraint , Reduce the free deformation length , Change the section form , Or if it's a little close, you can change the intensity f.

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

38 Why does steel beam design generally not use fully plastic ultimate moment strength , Only partial use of material plasticity , Even if the working state of the beam is in the elastoplastic working stage ? answer : Because steel is an ideal elastic-plastic body , Even if the working state of the beam is in the elastoplastic working stage , Material strength cannot be fully utilized . When calculating the bending strength of the beam, consider the plastic development ratio of the section, and do not consider the need to save steel . If it is designed by forming plastic hinges according to the section , It may make the disturbance of the beam too large , The compression flange loses local stability prematurely . therefore , When preparing steel structure design specifications , Only limited use of plasticity , Development depth of plasticity

Add picture comments , No more than 140 word ( Optional )

. 39 What should be checked in the strength checking calculation of steel beams ? answer : The bending strength should be considered in the strength checking calculation of the beam 、 Shear strength 、 Local bearing strength 、 Strength under complex stress and checking calculation converted stress , Among them, the calculation of bending strength is the primary . 40 How to control the rigidity of steel beam ? answer : The stiffness of the beam is measured by the deflection under load . The rigidity of the beam is insufficient , There is no guarantee of normal use . The stiffness requirement is the deflection of the beam v≤[v], To control the stiffness of the beam, it is necessary to control the deflection of the beam caused by the external load , The deflection of the beam can be calculated according to the methods of material mechanics and structural mechanics , It can also be obtained from the structural static calculation manual . Calculate the deflection of the beam

Add picture comments , No more than 140 word ( Optional )

When the value of , The load standard value taken shall be consistent with the attached table 2.1 The specified allowable deflection value

Add picture comments , No more than 140 word ( Optional )

Corresponding . 41 Try to describe the main factors that affect the overall stability bearing capacity of the beam ? answer : The critical load of the overall stability of the beam and the lateral bending stiffness of the beam 、 Torsional stiffness 、 The distribution of load along the beam span and the position of its action point on the section are related

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

43 Try to describe the design steps of composite section beam ?( A little ) answer :1、 Try to select the section , When selecting the section of the composite beam , First, the height of the bright section should be preliminarily estimated 、 Web thickness and flange size ;2、 Section checking calculation , Calculate various geometric data of the section according to the size selected , Such as moment of inertia 、 Section modulus, etc , Then check the calculation ;3、 Change of composite beam section along length ;4、 Calculation of flange weld of welded composite beam . 44 Types and functions of Web stiffeners of steel beams ? When the shear stability bearing capacity of the web is insufficient , Which stiffener should be set ? answer : The transverse stiffener mainly prevents the instability of the web caused by shear stress and local compressive stress , Longitudinal stiffeners mainly prevent web instability that may be caused by bending compressive stress , Short stiffeners are mainly used to prevent web instability that may be caused by local compressive stress . When the shear stability bearing capacity of the web is insufficient , Support stiffeners should be provided , Supporting stiffeners are transverse stiffeners that bear fixed concentrated loads or bearing reactions . Such stiffeners shall be set in pairs on both sides of the web , And the overall stability and end bearing calculation shall be carried out , Its section is often larger than the middle transverse stiffener . Calculation questions : 1 Check the strength of butt weld of I-section beam welded by three steel plates as shown in the figure . The dimensions are shown in the picture , Design value of axial tension acting on the section N=250kN, Design value of bending moment M=40kN.m, Shear design value V=200kN, The steel is Q345, Manual welding , The welding rod is E50 type , During welding, run on plates are used , Level III quality standard .

edit

Add picture comments , No more than 140 word ( Optional )

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

2 In the figure I32a The bracket is connected with the column with butt weld . The steel is Q235, Welding rod E43 type , Manual welding , use II Inspection quality standards for grade I welds . It is known that :I32a Cross sectional area of A=67.05cm2; Moment of resistance Wx=692.2cm2; Section area of Web AW=25.4cm2.Ix : Sx=27.5 , tw=9.5mm Try to follow 《 Steel gauge 》 and 《 Bridge gauge 》( The weld is of class I ) O, respectively, F The maximum of .

edit

Add picture comments , No more than 140 word ( Optional )

【 Explain 】 The internal force borne by the butt weld is :

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

edit

Add picture comments , No more than 140 word ( Optional )

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

Edit switch to center

Add picture comments , No more than 140 word ( Optional )

edit

Add picture comments , No more than 140 word ( Optional )

edit

Add picture comments , No more than 140 word ( Optional )

边栏推荐

- [AUTOSAR candrive 2. understand the mapping relationship between communication HOH, canid and pduid]

- NVIDIA NVIDIA released H100 GPU, and the water-cooled server is adapted on the road

- Check the sandbox file in the real app

- Interpretation of the paper: develop a prediction model based on multi-layer deep learning to identify DNA N4 methylcytosine modification

- [distinguish the meaning and usage of constant pointer and pointer constants const int * and int * const]

- 深度学习-神经网络

- 数据挖掘场景-发票虚开

- 【AUTOSAR COM 4.Com服务层模块的介绍】

- [AUTOSAR com 3. signal sending and receiving process tx/rx]

- [introduction to AUTOSAR com 4.com service layer module]

猜你喜欢

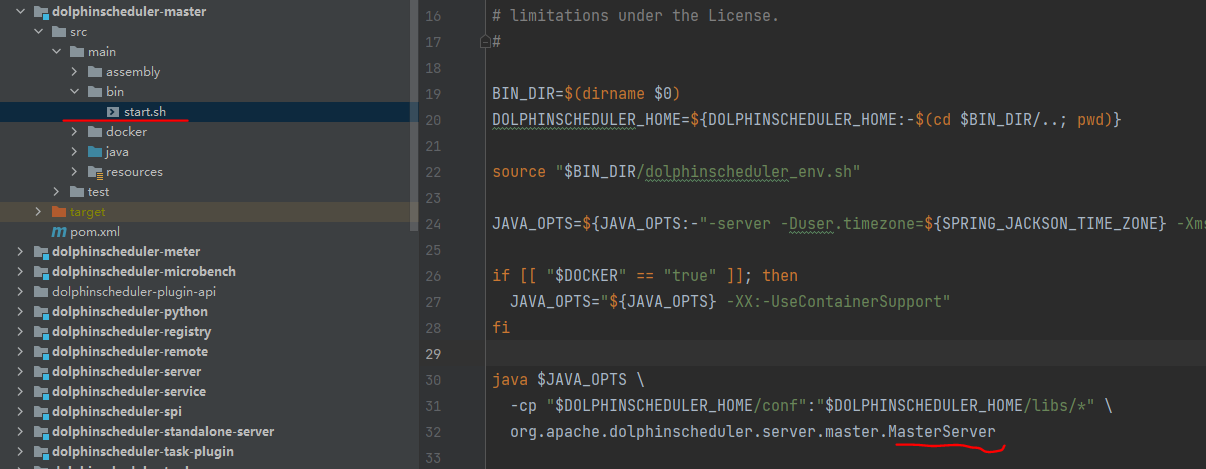

Talent column | can't use Apache dolphin scheduler? The most complete introductory tutorial written by the boss in a month

Analyze the pre integration of vio with less rigorous but logical mathematical theory

单片机学习笔记6--中断系统(基于百问网STM32F103系列教程)

高等代数100道题及答案解析

时间序列的数据分析(一):主要成分

数据挖掘场景-发票虚开

Baidu Shen Shuo: focus on the scene, deeply cultivate the industry, and bring practical results to enterprise Digitalization

【AUTOSAR COM 1.通信协议栈介绍】

ARM架构与编程6--重定位(基于百问网ARM架构与编程教程视频)

Interpretation of the paper: iterative feature representation method to improve the prediction performance of N7 methylguanosine (m7G) sites

随机推荐

Interpretation of the paper: iterative feature representation method to improve the prediction performance of N7 methylguanosine (m7G) sites

[talent column] can't you use Apache dolphin scheduler? It takes a month to write the most comprehensive introductory teaching [2]

[CAN总线的物理层 ]1.CAN/CANFD采样的点的内容分享

论文解读:《基于BERT和二维卷积神经网络的DNA增强子序列识别transformer结构》

Gartner research: how is China's digital development compared with the world level? Can high-performance computing dominate?

Check the sandbox file in the real app

【AUTOSAR DCM 1.模块简介(DSL,DSD,DSP)】

【基于UDS服务的BootLoader架构和刷写流程】

高等代数知识结构

Uni native plug-in development -- Youmeng one click login

Deep convolution generation countermeasure network

Using pycaret: low code, automated machine learning framework to solve regression problems

谈谈转动惯量

单片机学习笔记7--SysTick定时器(基于百问网STM32F103系列教程)

Interpretation of the paper: develop a prediction model based on multi-layer deep learning to identify DNA N4 methylcytosine modification

3.2daydayup举一反三:三天打鱼两天晒网式学习

Using pycaret for data mining: association rule mining

Using pycaret: low code, automated machine learning framework to solve classification problems

Object class

利用pycaret:低代码,自动化机器学习框架解决回归问题