当前位置:网站首页>Summary of common terms and knowledge in SMT chip processing industry

Summary of common terms and knowledge in SMT chip processing industry

2022-06-26 00:17:00 【Mounter】

smt A summary of common terms and knowledge in the chip processing industry

SMT The chip processing industry is the upstream industrial chain of all electronic products , There is a circuit board inside the electronic product , The circuit board contains many kinds of electronic components , Electronic components need to pass through SMT And DIP Assemble to the circuit board . Now, Jiangxi yingteli will introduce to you SMT Summary of common industry knowledge points and terms of patch processing (phase I) .

SMT The diameter of the winding disc of the part package 13 " ,7 " ;

2. The opening type of steel plate is square ﹑ triangle ﹑ circular , Stars , Benlei shape ;

3. Rosin based flux can be divided into four types : R﹑RA﹑RSA﹑RMA;

4. At present, solder paste is on the market , Actually only 4 Hours of viscous time ;

5.SMT Generally, the rated air pressure of the equipment is 5KG/cm2;

6.SMT Common inspection methods : Visual inspection ﹑X Light inspection ﹑ Machine vision inspection

7. at present BGA The main components of the material are tin balls Sn90 Pb10;

8. The weight ratio and volume ratio of tin powder to flux in the solder paste are correct 90%:10% ,50%:50%;

9. at present SMT The most commonly used solder paste Sn and Pb The content of each is : 63Sn+37Pb;

10. The common material tray bandwidth is 8mm The feeding distance of the paper tape tray is 4mm;

11.SMT The mounter should first paste small parts , Large parts are pasted on the back ;

12.SMT Parts can be divided into... According to the presence or absence of part feet LEAD And LEADLESS Two kinds of ;

13. SMT There is no in the process LOADER It can also produce ;

14. SMT The common basic process of manufacturing is loading machine - Solder Paste Printer - High speed machine - Universal machine - Reflow soldering - Plate retractor ;

15. When the temperature and humidity sensitive parts are opened , The color displayed in the circle of the humidity card is blue , Parts can only be used ;

16. Temperature curve of reflow furnace the maximum temperature of the curve 215 The degree is the most suitable ;

17. The manufacturing method of steel plate is laser cutting ﹑ Electroforming ﹑ Chemical etching ;

18.ICT The test is a needle bed test ;

19. Types of reflow soldering : Hot air welding furnace ﹑ Nitrogen arc welding furnace ﹑ Vacuum welding furnace ﹑ Infrared welding furnace ;

20.SMT Methods that can be used for part sample test : Streamline production ﹑ Handprint machine mounting ﹑ Handprint and hand mounting ;

21. frequently-used MARK Shape has : circular ,“ Ten ” The font ﹑ Square , The diamond , triangle , Swastika ;

22.SMT The reflow soldering curve of segment is improperly set , It is the preheating zone that may cause the parts to crack ﹑ Cooling zone ;

23. SMT Uneven heating at both ends of segment parts is easy to cause : Air welding ﹑ Deviation ﹑ tombstone ;

24. SMT The maintenance tools are : Soldering iron ﹑ Hot air extractor ﹑ Tin suction gun , Tweezers ;

25.QC It is divided into :IQC﹑IPQC﹑.FQC﹑OQC;

- ICT The test can measure electronic parts by static test ;

27. The measurement curve shall be re measured for the change of reflow soldering part replacement process conditions ;

28. The solder paste detector uses light to measure : Solder paste flatness ﹑ Thickness of solder paste ﹑ Width of solder paste printing ;

29.SMT Part Feida has a vibrating feeder ﹑ Disc feeder ﹑ Coil feeder ;

30.SMT Mechanism classification of equipment : Cam mechanism ﹑ Side bar mechanism ﹑ Screw mechanism ﹑ Sliding mechanism ;

31. High speed chip mounter can mount resistors ﹑ capacitance ﹑ IC﹑ The transistor ;

32. The production line of high-speed machine and universal machine shall be balanced as far as possible ;

33. SMT Cause of short circuit caused by poor solder paste printing :

a. Insufficient metal content in solder paste , Cause collapse

b. The opening of steel plate is too large , Cause too much tin

c. Poor quality of steel plate , Poor tin deposition , Change the laser cutting template

d. There is solder paste on the back , Reduce the scraper pressure

The main purpose of each zone of general reflow furnace :

a. Purpose of preheating zone : The solvent in the solder paste volatilizes .

b. Purpose of uniform temperature zone : Flux activation , Remove oxides ; Evaporate excess water .

c. Purpose of back welding area : Solder melts .

d. Purpose of the cooling zone : Alloy solder joint formation , The part foot is connected with the pad as a whole ;SMT The main reasons for the production of tin beads in :

PCB Poor board design 、 Poor design of steel plate opening 、 The setting depth or pressure is too large 、 The rising slope of temperature control curve is too large , The solder paste collapsed 、 The solder paste viscosity is too low .

In the follow-up, we will present the relevant contents of the second issue to you .

Jiangxi yingteli is a professional SMT Patch processing 、PCBA Patch processing 、PCBA plate 、OEM OEM materials 、DIP Post welding and testing 、 Procurement of electronic components 、 Integrated manufacturing service provider for assembly and packaging of finished products , Welcome to inquire about chip processing business

边栏推荐

猜你喜欢

Literature research (IV): Hourly building power consumption prediction based on case-based reasoning, Ann and PCA

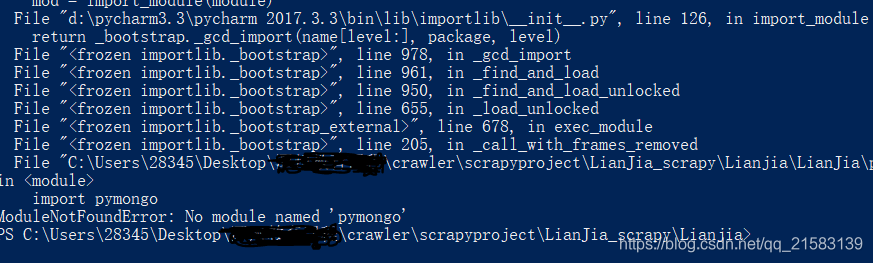

About the solution to prompt modulenotfounderror: no module named'pymongo 'when running the scratch project

Literature research (I): hourly energy consumption prediction of office buildings based on integrated learning and energy consumption pattern classification

Regular expression introduction and some syntax

Installation of third-party library iGraph for social network visualization

Redis jump table

ORA-01153 :激活了不兼容的介质恢复

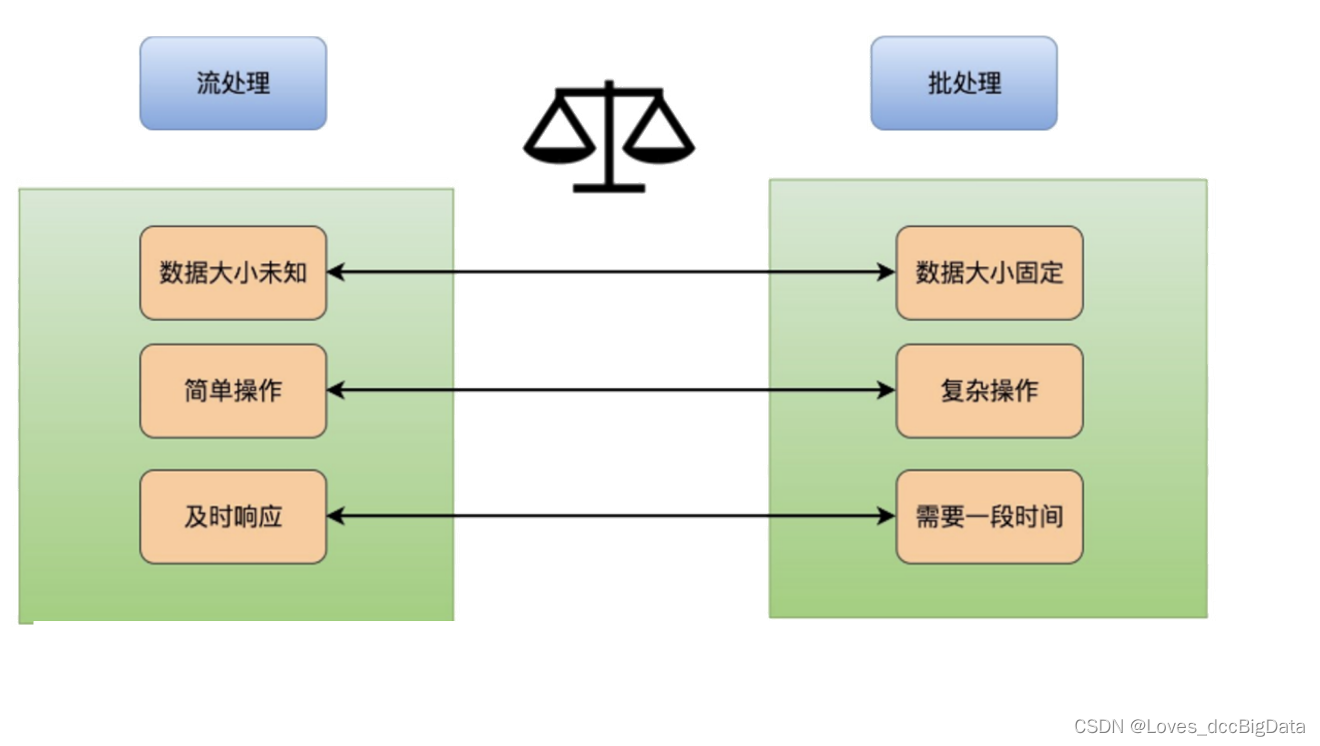

11.1.1、flink概述_flink概述

idea设置mapper映射文件的模板

10.4.1 données intermédiaires

随机推荐

My blog is 2 years old and 167 days old today. I received the pioneer blogger Badge_ Old bear passing by_ Sina blog

毕业季 | 在不断探索中拟合最好的自己

Smt贴片机工作流程

贴片加工厂家讲解__ICT是什么?主要测试什么?ICT测试的优缺点?

EBS r12.2.0 to r12.2.6

Types of feeder and how to work

《SQL优化核心思想》

渲云携手英特尔,共创云渲染“芯”时代

no_expand和use_concat

Smt贴片加工出现元件立碑的解决方法

dbca静默安装及建库

Multi-Instance Redo Apply

Xiaohongshu microservice framework and governance and other cloud native business architecture evolution cases

Darkent2ncnn error

深圳台电:联合国的“沟通”之道

86.(cesium篇)cesium叠加面接收阴影效果(gltf模型)

Sentinel of redis

SMT贴片加工PCBA板清洗注意事项

About Simple Data Visualization

Detailed explanation of redis