当前位置:网站首页>Types of feeder and how to work

Types of feeder and how to work

2022-06-26 00:16:00 【Mounter】

Mounter is also called mounter , yes SMT A very important core machine in the industry ,SMT The production efficiency and capacity of the whole line are determined by the chip mounter , There are also high-speed in the industry 、 Medium and low speed ( multi-function ) The difference between machines , The mounting head controlled by the mounting cantilever of the mounting machine ( The mounting head is equipped with a suction nozzle ) Suction nozzle to pick up components , Attach different components to PCB Specified pad position ; How does the suction nozzle pick up components , It is through the Feida that I will tell you next (feeder), It is also called feeder in Chinese to realize this operation .

Feeder of the mounter (feeder) Feida has many styles , Here are some types of

Cassette feeder , Belt feeder , Tube feeder , Tray feeder

Belt feeder

The belt feeder is one of the most commonly used feeders in the chip mounter , The traditional structure has wheel type 、 Claw type 、 Pneumatic and multi pitch electric , Now it has developed into high-precision electric type , The high-precision electric type is opposite to the traditional structure , Higher transmission accuracy 、 Faster feeding 、 More compact structure , More stable performance , Greatly improve the production efficiency

Basic specifications of strip material

· Basic width :8 mm,12 mm,16 mm,24 mm,32 mm,44 mm and 52 mm Etc ;

· Band spacing ( Adjacent component center to center ):2 mm,4 mm,8 mm,12 mm and 16 mm;

· There are two kinds of banded materials : Paper and plastic ;

Tube feeder

The tube feeder usually uses a vibrating feeder to ensure that the components in the tube continuously enter the suction position of the patch head , commonly PLCC and SOIC It is in this way that the material is supplied . The tubular feeder has a good protective effect on the pins of components , Poor stability and standardization , Low production efficiency

Cassette feeder

The box feeder is also called vibrating feeder , The working mode is to put the components into the molded plastic box or bag freely , Through the vibrating feeder, the components are sent to the mounter in turn , It is suitable for nonpolar rectangular and cylindrical components , However, it is not applicable to feeding the components into the mounter successively through the vibrating feeder or feeding pipe , This method is usually used to melt polar elements and small profile semiconductor elements , Only applicable to polar components .

Tray feeder

The tray feeder is divided into single-layer structure and multi-layer structure . The single-layer tray feeder is directly installed on the feeder frame of the mounter , Occupy multiple locations , It is suitable for the situation that there are not many pallet materials ; The multi-layer tray feeder has multi-layer automatic transfer tray , Small footprint , Compact structure , Disk mounted components are mostly various IC Integrated circuit components

边栏推荐

- 使用coe_load_sql_profile.sql固定执行计划

- Redux workflow + complete code of small examples

- Using swiper to realize the rotation chart

- JS to input the start time and end time, output the number of seasons, and print the corresponding month and year

- Apache基金会正式宣布Apache InLong成为顶级项目

- logstash丢弃没有精准匹配到文件名的日志数据

- Simulink求解器综合介绍

- 被新冠后遗症困住15个月后,斯坦福学霸被迫缺席毕业典礼,现仍需每天卧床16小时:我本该享受20岁的人生啊...

- On the use of bisection and double pointer

- 实现异步的方法

猜你喜欢

How postman tests interfaces that require login

被新冠后遗症困住15个月后,斯坦福学霸被迫缺席毕业典礼,现仍需每天卧床16小时:我本该享受20岁的人生啊...

11.1.1、flink概述_flink概述

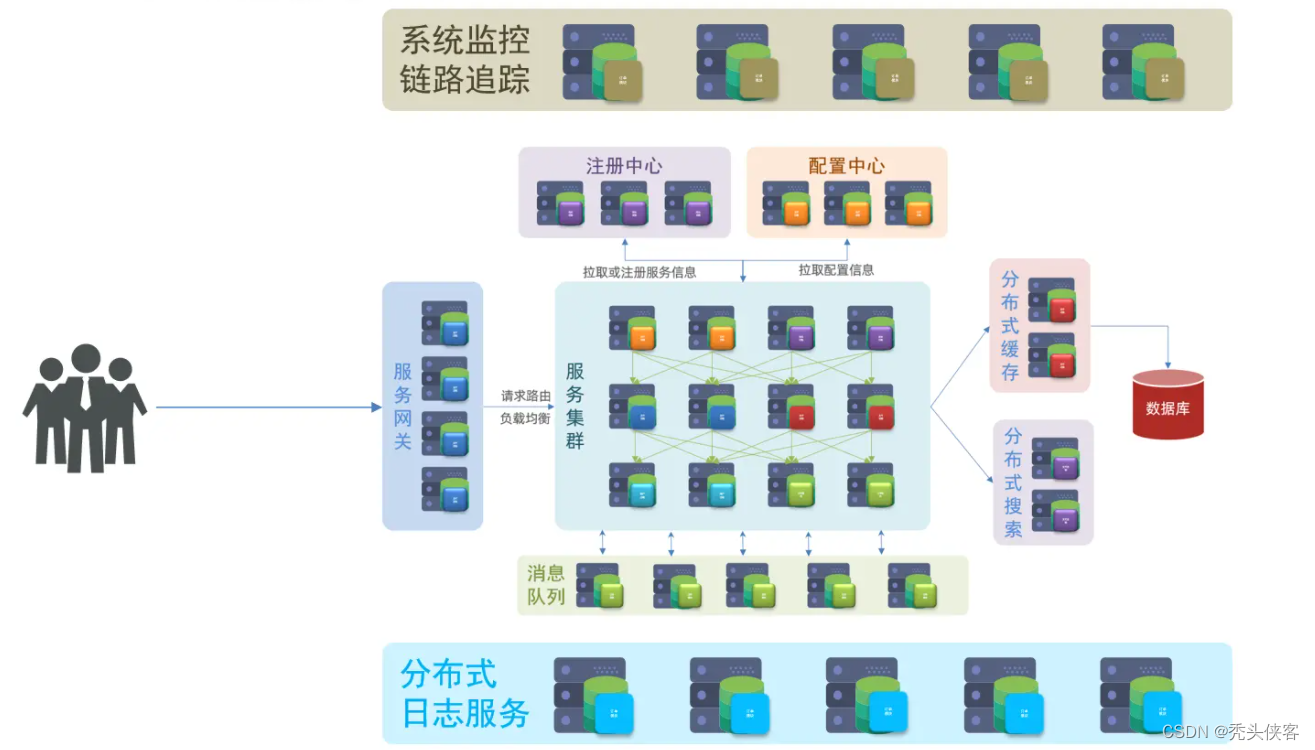

What is micro service

元宇宙中的法律与自我监管

Redis之跳跃表

10.2.3、Kylin_kylin的使用,维度必选

My blog is 2 years old and 167 days old today. I received the pioneer blogger Badge_ Old bear passing by_ Sina blog

(Reprint) visual explanation of processes and threads

10.2.3、Kylin_ The dimension is required for kylin

随机推荐

(Reprint) visual explanation of processes and threads

Common problems encountered when creating and publishing packages using NPM

10.4.1、数据中台

86.(cesium篇)cesium叠加面接收阴影效果(gltf模型)

文献调研(一):基于集成学习和能耗模式分类的办公楼小时能耗预测

网络连接验证

Some basic uses of mongodb

SSL unresponsive in postman test

【ROS进阶篇】第一讲 常用API介绍

Mysql5.7.31自定义安装详细说明

P3052 [USACO12MAR]Cows in a Skyscraper G

Recommended system design

Apache基金会正式宣布Apache InLong成为顶级项目

DNS复习

11.1.1、flink概述_flink概述

POSTMAN测试出现SSL无响应

Daily question brushing record (IV)

huibian

On the use of bisection and double pointer

Mysql5.7 is in the configuration file my Ini[mysqld] cannot be started after adding skip grant tables