当前位置:网站首页>Etching process flow for PCB fabrication

Etching process flow for PCB fabrication

2022-06-24 17:27:00 【PCBA chengyaoer】

pcb The process flow of plate fabrication and etching is divided into : Peel the membrane 、 Circuitry etching 、 Tin stripping ( lead ) Let's introduce these three processes in detail :

Peel the membrane

stay pcb Plate production , Only 2 individual step You will need to peel the film . After etching the inner circuit D/F Before stripping and etching of the outer circuit D/F Stripping ( If the outer layer is made into a negative process ).D/F The stripping process is simple , All use wired horizontal equipment , Most of the chemical solutions used are at the concentration weight ratio 1~3%NaOH or KOH.

Circuitry etching

1. Copper etching mechanism

(1) Copper ion is easy to form copper hydroxide precipitation in alkaline environmental solution , In order to prevent this precipitation , It is necessary to add enough ammonia water to produce the wrong ion group of ammonia and copper to inhibit the precipitation . It can also make the original large amount of copper and the copper that continues to dissolve form a very stable copper ion in the liquid . Like this divalent ammonia copper cross ion, it can be used as an oxidant to oxidize and dissolve the zero valent metal copper , But in the oxidation-reduction reaction process, there will be univalent cuprous ion .

The solubility of cupric ion in this reaction is very poor , Ammonia water is required 、 Ammonia ion and a large amount of oxygen in the air help to make it continue to oxidize into soluble divalent copper ion , Then it becomes the oxidant of copper corrosion and continues to etch copper repeatedly until the amount of copper is too much and slows down . Therefore, in addition to removing ammonia odor, the general etching machine can supply fresh air to accelerate copper corrosion .

(2) In order to make the above copper corrosion reaction proceed more quickly , There are many additives in the etching solution , for example :

a. Accelerators Acceletator It can make the above oxidation reaction faster , And prevent the precipitation of cuprous wrong ions .

b. Revetment agent (Banking agent) Reduce side erosion .

c. Depressants Suppressor Restrain ammonia from flying away under high temperature , Inhibit the precipitation of copper and accelerate the oxidation reaction of copper corrosion .

2. equipment

(1) In order to increase the corrosion rate, it is necessary to increase the temperature to 48℃ above , Therefore, there will be a large amount of ammonia odor, which needs to be properly ventilated , However, when the exhaust volume is too strong, a large amount of useful ammonia will be pumped away, resulting in waste , An appropriate throttle valve can be added to the exhaust pipe for control .

(2) The etching quality is often due to the pool effect (pudding) And limited ,( The fresh liquid medicine is blocked by water , The pool effect that cannot effectively react with the copper surface ) That's why pcb The front part of the board often has over etch The phenomenon , Therefore, the following points should be considered in equipment design :

a. The board is thin and the line faces down , The thicker line faces up .

b. On the nozzle , The lower liquid injection pressure is adjusted to compensate , Adjust the difference according to the actual operation results .

c. The advanced etcher can control when the circuit board enters the etching section , The first few groups of nozzles will stop spraying for a few seconds .

d. There are designed vertical etching methods , To solve the problem of inequality on both sides , But it is seldom used in China .

3. Add control

Automatic replenishment the replenishment liquid is ammonia water , Usually with a very sensitive hydrometer , And feel The temperature at that time ( Because the specific gravity is different at different temperatures ), Set the upper and lower limits , Start adding ammonia above the upper limit , Do not stop until it is below the lower limit . At this time, the location of the detection point and the nozzle where ammonia is added are very important , To avoid detection delay and Adding too much ammonia wastes the cost ( Because it will overflow )

4. Daily maintenance of equipment

(1) Do not let the etching solution have sludge produce ( Light blue univalent copper sludge ), So composition control is very important , In especial PH, Too high or too low can cause .

(2) Keep the nozzle free from blockage at all times .( The filtration system shall be kept in good condition )

(3) The specific gravity induction addition system shall be calibrated regularly .

Tin stripping ( lead )

Tin stripping ( lead ) This step is purely for processing , No added value , But in order to ensure the quality of the product , Still need to pay attention to the following points :

(1) Tin stripping ( lead ) Liquid is usually two liquid type or single liquid type provided by the supplier , The stripping methods are semi soluble and fully soluble , The solution is composed of fluorine series /H2O2,HNO3/H2O2 etc. .

(2) Whatever the formula , The following potential problems may occur during operation :

a. Attack the copper surface

b. The process after stripping the unfinished influence

c. Waste liquid treatment

In order to ensure the stability of product quality , Tin stripping ( lead ) Good equipment design and pre process tinning are required ( lead ) Thickness control and management of medicine liquid efficacy . How to judge the quality of etching ? It is mainly based on the following points :

- Protruding edge

- Lateral erosion

- Etch factor

- Over erosion

- Etched surface finish

- Whether the line spacing is clear

By facing up to pcb Introduction to the etching process of plate making , I'm sure you're right pcb Etching will also have a new understanding .

More content can be seen in official account. :PCBA Information sharing

PCB Design -PCB Board making -SMT Patch -BOM It can be made with orders

https://www.jdbpcb.com/MC https://www.jdbpcb.com/MC

https://www.jdbpcb.com/MC

边栏推荐

- How to learn go language happily? Let's go!

- Zblog determines whether a plug-in installs the enabled built-in function code

- Conditional competition overview

- How to build RTSP test URL in Intranet Environment

- 03. Tencent cloud IOT device side learning -- overview of mqtt control package

- Tencent cloud database mysql:sql flow restriction

- [play with Tencent cloud] play with cloud database mysql

- Analysis and introduction of NFT meta universe source code construction

- Low education without food? As an old Android rookie in the past six years, I was the most difficult one

- Construction scheme of campus network clock system (standardized examination room)

猜你喜欢

随机推荐

Implement typescript runtime type checking

Elastic searchable snapshot function (frozen Tier 3)

The RTSP video image intelligent analysis platform easynvr cascades to the superior platform through the national standard for playback optimization

Go kit microservice integrates Promtheus to solve monitoring alarm problems

How to use SEO to increase the inquiry volume?

Operation and maintenance guide | cos back source setting practice

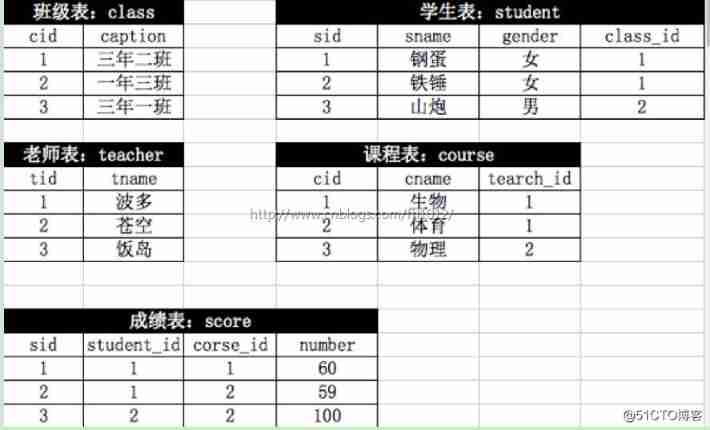

MySQL learning -- table structure of SQL test questions

About with admin option and with grant option

March 27, 2021: give you a head node of the linked list, and rotate the linked list

Cloud MySQL importing cloud data warehouse PostgreSQL best practices

[DB Bao 45] MySQL highly available mgr+consult architecture deployment

On N handshakes and M waves of TCP

How to compile and debug go runtime source code

Quick view of product trends in February 2021

Will the easycvr video channel of the urban intelligent video monitoring image analysis platform occupy bandwidth after stopping playing?

FPGA systematic learning notes serialization_ Day9 [serial port printing of PS terminal of Xilinx zynq7000 series]

Do you charge for PDF merging software? Programmers make one by themselves

VBA Daniel used the nested loop

Using consistent hash algorithm in Presto to enhance the data cache locality of dynamic clusters

AFG EDI requirements details