当前位置:网站首页>Case analysis: using "measurement" to improve enterprise R & D efficiency | ones talk

Case analysis: using "measurement" to improve enterprise R & D efficiency | ones talk

2022-06-24 23:11:00 【Everything ones】

6 month 17 Japan , stay 「 Lean Software Engineering Conference 」 On ,ONES Dongxiaohong, a consultant for R & D efficiency improvement, made a presentation entitled 《 Interpretation of R & D effectiveness measurement scenarios 》 Speech . Through two scenarios of efficiency improvement , Discuss how to pass 「 Measure 」 Help enterprises solve specific problems , Improve R & D Efficiency .

The following is the main content that dongxiaohong shared that day .

What is R & D effectiveness ?

In consultation , Customers often ask :「 How to improve R & D Efficiency 」? however , The understanding of R & D effectiveness varies greatly : Some people think that effectiveness is a set of quantitative indicators , Some people think that efficiency is the saturation of human resources , Others believe that efficiency is engineering practice and so on .

Peter Drucker, the master of management, once said :「 Efficiency is doing things the right way , And efficiency is doing the right thing .」 We understand R & D effectiveness , Is dynamic 、 Do the right thing sustainably . The so-called doing the right thing , It means that we find the goal individually or as a team 、 Direction , Can bring value to customers , So as to help our organization realize business value . meanwhile , Complete the work according to the standard process , Do more 、 Fast 、 Good again 、 Another province , This is what we understand 「 R & D effectiveness 」.

When we talk about R & D metrics , We are used to talking about it 「 It's not something 」—— It's not just a set of data , It is the information behind our data ; It is not a pre-existing indicator , It is to determine the problem to be solved and the goal to be achieved , To design a set of indicators ; It is not a fixed activity of the whole software development , It is continuous feedback in lean thinking 、 The idea and idea of continuous improvement .

Enterprise efficiency improvement case sharing

Next , Share two scenarios of the same company , We hope that the customers can understand how we passed 「 Measure 」 To solve specific problems , And what good practices we have while solving problems . The selected case is an Internet enterprise , The company size 2000 people ,9 Business units , Technical personnel 900+.

Scene one

The pain point of this scenario is stability . The company structure is 「 Small front desk + Tai Chung Tai 」, The capital loss caused by the failure is huge , CIRC interviewed for rectification , Partner complaints , Lost a lot of channels . For the R & D side , They don't have the data 、 Tired of fighting a fire , The stability quality of the current system cannot be clearly stated , Always carry the pot for a third party . This was the pain point of the company at that time .

Based on this sore point , We have set the following goals :

Each business unit shall establish stability baseline data —— That is to say 「 Where are we 」?

Each business department sets stability goals according to its own business —— That is to say 「 Where are we going 」?

Repeat the disk regularly for the stability fault , Gradually improve stability ;

Regularly publish the stability report of each business department , Set up a stability benchmark , Copy and promote excellent cases ;

Improve the monitoring mechanism , Improve the failure rate of monitoring and detection .

Next , Let's look at the stability measurement data observation of this case .

Observation data 1 : Through the measurement of fault related data, its asset loss is obtained , Including direct asset loss and potential asset loss . After we set our goals , Asset losses fell the following year 50%, The asset loss time is increased to 30 Within minutes . Of course , Stability improvement , It's a systematic project , We still have a lot to do : In advance , We define the fault level ( for example , Level I requirements 5 Respond in minutes , Level IV requires response within half a day ); In the matter , We also need to do emergency coordination for failures , How can we cooperate 、 How to solve the fault ; After the event , Scheme for improving the whole system , Improve the stability of future operation .

Observation data II : Measure by analyzing the cause of the failure , Form improvement measures , The business stability improved in the following year 58%. We analyze the cause of the fault and the type of improvement measures , See what improvements we can make to avoid failures , At the same time, prevention and improvement .

Observation data III : Through the analysis of fault discovery form , For the faults found on the user side , Reverse compensation monitoring logic , The next year, the fault occurs Increase of current rate 20%.

Observation data IV : Through the regular stability report to the nine business divisions , Visualize quality . Give Way CTO、CEO See the overall quality , At the same time, let the experience of excellent departments be copied and popularized in the organization .

Scene two

Another scenario is the case of demand value measurement , Let's take a look at the pain points :

Pain points at the company level : A lot of resources have been invested , But I don't know how to solve the demand blowout and whether to maximize the value ;

Pain points on the technical side : Technology output cannot be measured , It is not clear how many products have been made ;

Pain points on the product side : There are many sources of demand , Every business is said to be an urgent need , Unable to systematically design the product ;

The pain points of technicians : Write the code down , Do not understand the value of actual needs , As a result, the delivered version can not meet the expectation , Unable to get the sense of achievement brought by the job .

Based on these pain points , We designed the goal and steps of demand value measurement . The goal is Quantify the actual value of the demand , Prioritize requirements , Invest resources accurately , Maximize value ; Improve the recognition of the R & D side to the demand business objectives , And track the estimated and actual value deviation , Improve product design .

in addition , The realization steps of demand value degree are divided into three steps :

First step , Sort out the demand value classification according to the current business objectives and past demands , Recommend from 「 The value of the business 」 as well as 「 Enterprise value 」 Two aspects of classification ;

The second step , In the project collaborative management tool configuration and traceability process , Here's the picture :

The third step , The conformity of the value of regular re offer , Analyze the deviation problem , Observation effect .

Follow the steps above , First , Analyze the conformity of demand value . We investigated a business unit , A quarter has 46% The demand of did not meet the expectation ; secondly , We divided the whole business into four cross functional teams , Let the teams compare horizontally , Imitate each other 、 Study .

Last , Is the overall demand value compliance . such as , Strategic cooperation has reached 100%, Increasing revenue is also 100%. And improve the conversion rate 、 Risk avoidance and other indicators , Not meeting expected value of the demand .

According to customer feedback , The benefits of this method of analysis are It has aroused the enthusiasm of development . They are more willing to help the business achieve its goals through technical means , Because he 「 Know what it is , Know why 」, Can better understand this business .

「 Measure 」 Thinking and inspiration

in addition to , I would also like to share our thoughts on R & D measurement .

The first on the one hand, , Efficiency improvement landing , Standard tools first . First , Sort out the process specifications , Ensure that a series of consensus words are formed throughout the organization . for example , Awareness of goals 、 Uniform terminology 、 Serial connection of business and data flow 、 Unit of measure / Unification of measurement sources, etc ; secondly , Solidify process specifications through tools , Carry out measurement index embedding ; Last , By measuring the presentation layer , For each perspective 、 Experts in various fields present data they care about .

In the second , Measurement needs to be customized . For R & D performance measurement , The enterprise needs to combine the business objectives of the stage 、 Management honesty 、 Problems to be solved, etc , Tailored metrics .

The third aspect , Goodhart's law tells us :「 Once an indicator changes , It is not a good measure .」 So metrics have to be weighed , The design of R & D metrics should also have a traction effect , Don't blindly pursue the improvement of numbers , It depends on whether the problem is really solved . also , Metrics should avoid being directly linked to performance . If performance measurement becomes a set goal , People tend to optimize it , Whatever the consequences , In this way, the measurement loses its meaning .

Scan the code to get the full version of the speech video and PPT

边栏推荐

- gocolly-手册

- Accounting standards for business enterprises application [5]

- 加分利器 不负所托 | 知道创宇获攻防演练防守方感谢信!

- 【武汉大学】考研初试复试资料分享

- Selection (028) - what is the output of the following code?

- Dig deep into MySQL - resolve the clustered index / secondary index / federated index of InnoDB storage engine

- Uncover the secrets of Huawei cloud enterprise redis issue 16: acid'true' transactions beyond open source redis

- Cases of addition, deletion, modification and search of C # learning for two years and C # import and export (de duplication)

- 对抗训练理论分析:自适应步长快速对抗训练

- docker安装mysql-简单无坑

猜你喜欢

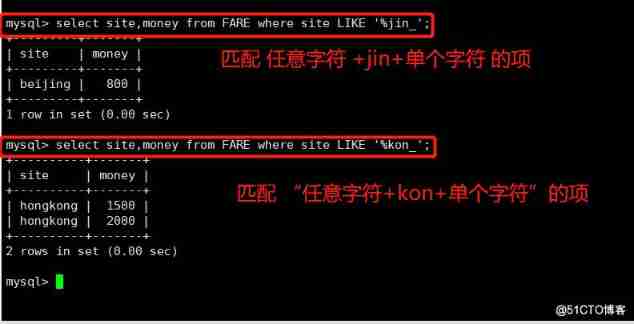

High level application of SQL statements in MySQL database (I)

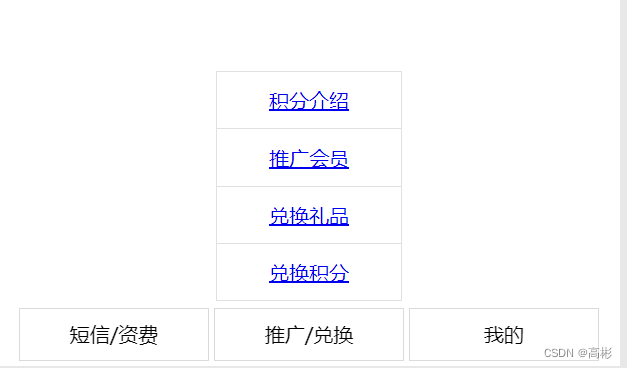

Dynamic menu, auto align

大厂面试必问:如何解决TCP可靠传输问题?8张图带你详细学习

Canvas to add watermark to pictures

Paddledtx v1.0 has been released, and its security and flexibility have been comprehensively improved!

23研考生注意啦!备考期间最容易中招的骗局,居然是它们?!

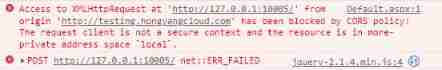

Solve the problem of non secure websites requesting localhost to report CORS after chrome94

Vulnhub Vegeta: 1

Theoretical analysis of countermeasure training: adaptive step size fast countermeasure training

Docker installation MySQL simple without pit

随机推荐

Building Survey [2]

Construction equipment [6]

F29oc analysis

JD 618 conference tablet ranking list announced that the new dark horse brand staff will compete for the top three, learning from Huawei, the leader of domestic products

laravel 创建 service层

China Sky Lantern market trend report, technical dynamic innovation and market forecast

Dig deep into MySQL - resolve the clustered index / secondary index / federated index of InnoDB storage engine

Financial management [2]

Cat write multiline content to file

Vulnhub Vegeta: 1

【nvm】

02_SpingBoot 入门案例

Research Report on solar battery charger industry - market status analysis and development prospect forecast

The extra points and sharp tools are worthy of the trust | know that Chuangyu won the letter of thanks from the defense side of the attack and defense drill!

shopee开店入驻流水如何提交?

推送Markdown格式信息到釘釘機器人

02_ Springboot starter case

Attackg: constructing technical knowledge graph from cyber thread intelligence reports

vulnhub Vegeta: 1

Tech talk activity review kubernetes skills of cloud native Devops