当前位置:网站首页>1.3----- simple setting of 3D slicing software

1.3----- simple setting of 3D slicing software

2022-06-22 19:47:00 【cbirdfly.】

Now at home level 3D There are three main steps in using a printer ( in the light of FDM type ): modeling ——》 section ——》 Print .

Simplify 3D Slicing Software (4.0.1) download :https://www.cxsw3d.com/qitagongju/64-365.html

1. modeling : In fact, students majoring in machinery should be familiar with , Just use Creo,SolidWorks,UG,Catia And other things that software often does . then 3D Printing is slightly different , The final output of mechanical design is engineering drawing , That is, the tolerance is marked , Machining drawing of 2D drawing and material data . and 3D After the design is completed, the general output of printing is STL file ,STL The file will be sent to slicing software for slicing , So as to obtain the movement track of the nozzle .

2. section : This is going to STL The file is automatically sliced by algorithm , There are mainly two slices , One is Slices of entities , The other one is Supported slice .STL The file contains only entities , Does not include support . Support is actually very simple to understand , For example, you designed a suspended structure , This structure no matter how you put it , There is a section in the air , Do not touch the printing platform . At this time, we need support . For example, the hole in the following figure , The software will automatically generate the supporting structure when slicing . The support will drag the suspended part of the material , So as to reduce the occurrence of printing errors . After slicing , Will generate a G Code file , This document will guide the movement of the nozzle , Print out entities layer by layer .

3. Print : This step actually has two parts. One is Commissioning of the machine ( Equipment environment preparation ), The other is Machine printing . The debugging of the machine means that the machine should be debugged to the best working state , for example : Leveling of the platform , Loading of the printing tray, etc . This is actually very simple , When the printer doesn't go wrong , Just plug in and load G The memory card of the code can be directly punched . But if something goes wrong with the printer , For example, printing failed , such as Edge warping , Plug , Broken material And so on , You need to find out the problem , There may be a problem with the slice parameter settings , Or printer hardware problems , Need to debug , solve the problem . So the ability to debug and solve problems is also very important . The working principle of the printer is also very simple to understand , Namely MCU Read the memory card G Code , Control the movement of multiple stepping motors , The stepping motor drives the nozzle to move , Extrude print material , To print out the entity .

Slicing Software :

Just started 3D When the printer , Used to Simplify 3D This slicing Software . Later, the computer was changed , Just use it Cura, A few days ago, I want to print a large structure , It's basically my one 3D The printer is out of range . This big structure , use Cura section , To print 58 Hours , I fuck . I didn't consider changing the software at that time , But I was really surprised .

Because the object is large , Insufficient material in the material tray , So I took a roll of black consumables that I had left at home for half a year , Something went wrong :3D Printer consumables are damp

And then there's no way , Got a new roll of supplies , For a long time , It's finally over . I don't know what to think , Want to try another slicing Software , So he took it out again Simplify 3D This slicing software found , Everything was startled , This slice is really fast .Cura Cutting this structure is directly stuck , I refer to B standing Up A tutorial for :Simplify 3D Print slice tutorial , Reconfigured slice parameters , Half the time is lost , Down to 20 More than one hour ... I was so excited at that time , ha-ha .

and Simplify 3D This software generates support , It's beautiful and easy to disassemble ,Cura The support is ugly , And hard to dismantle , It's a long time , It should not be used later Cura It's sliced .

Parameter setting :

You can go to this if you need to experience more detailed setting steps UP In the tutorial of :Simplify 3D Slicing tutorial

Here is a record of my simple setup steps :

Software use : Rotate with the left mouse button , The middle mouse button automatically returns to its original position , Right click to pan .

Set up :

1. Set the size of the printing platform and the type of printer , And speed units .

2. Extrusion settings

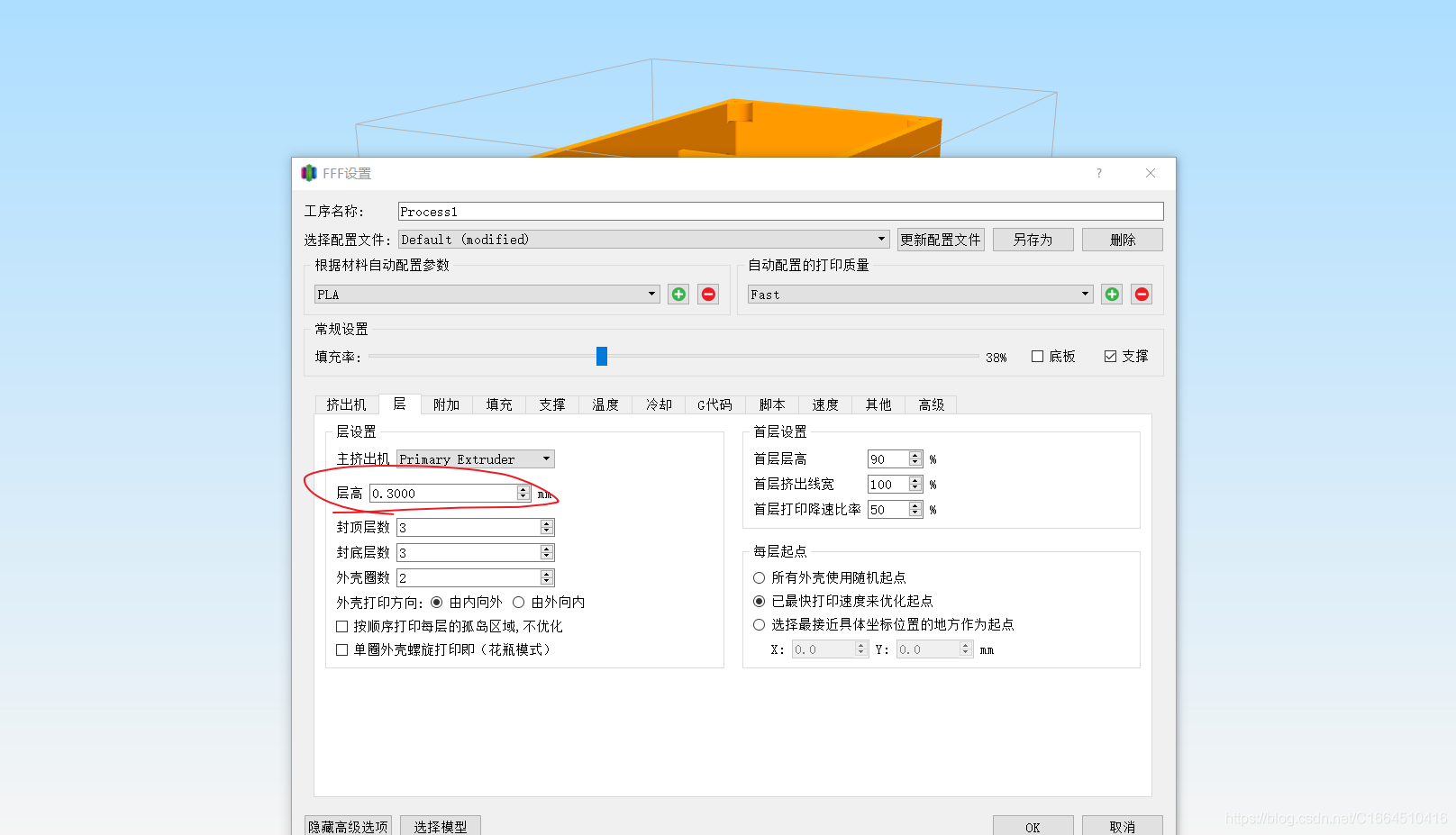

3. The height : This and Print fineness and Overall printing speed of .

4. additional : Only the skirt is set here , The skirt edge is to print a few circles on the outside , Make sure there is no problem with the nozzle .

5. fill

6. brace

7. temperature : By default, there is no hot bed temperature , So we need to manually add the temperature of the hot bed , We need to add it manually .

8. cooling : Set to step cooling , Increase the adhesion viscosity of the bottom layer

9. Script : This is actually Start printing and End printing The position of the nozzle at that time , All to set , Otherwise, it will stop on the model , It will burn the model .

; Start script

G92 Z0;

G0 Z10 F300;

G28;

G1 Z5 F300;

G1 X0 Y0 F3600;

G1 Z0.2 F300;

G92 E0;

G1 E8 F300;; End script

M107;

G92 E0;

G1 E-2 F300;

G1 X205 Y205 F2000; Move to the upper right corner (X:205mm Y:205mm), This should be set according to the size of your printer

M104 S0 ; turn off extruder

M140 S0 ; turn off bed

M84 ; disable motors10. Speed

11. senior

12. other

This contains a bridge setting , But I don't think this bridge is reliable , Sometimes support generation is unreasonable because of this setting . If the support is automatically generated , After slicing, take a look at the support generation , Prevent problems .

边栏推荐

- Teachers, I want to ask you a question. I run flinkcdc locally to synchronize MySQL data. The timestamp field parsing is normal,

- 下拉刷新及上拉加载更多的ListView

- AB打包有的Shader没有触发IPreprocessShaders的回调

- 数组对象根据id一 一对应填入(将arr1填入arr2中)

- Solution de pin hors grille dans altium designer

- 结构型模式之适配器模式

- c# winform 嵌入flash

- 知识蒸馏之Focal and Global Knowledge Distillation for Detectors

- canvas给图片画框框

- 实践出真知:全网最强秒杀系统架构解密,不是所有的秒杀都是秒杀!!

猜你喜欢

what? Homekit, Micah, aqara and other ecosystems can also be linked with tmall elf ecology through zhiting?

shell脚本详解(二)——条件测试、if语句和case分支语句

数商云:解析B2B2C多用户商城系统架构设计思路,开启智能商城新时代

结构型模式之适配器模式

常用技术注解

Shell编程规范与变量

Implementing Domain Driven Design - using ABP framework - solution overview

第一章 力扣热题100道(1-5)

C#,入门教程——关于函数参数ref的一点知识与源程序

Flutter系列-搭建Flutter开发环境

随机推荐

Agent model of structured model

NAND闪存(NAND Flash)颗粒SLC,MLC,TLC,QLC的对比

取zip包中的文件名

Thread pool: reading the source code of threadpoolexcutor

老师们,我想请教一个问题,我本地跑flinkcdc同步mysql数据timestamp字段解析正常,

mini-Web框架:模板替换与路由列表功能开发 | 黑马程序员

Ts as const

0.1-----用AD画PCB的流程

Shell script explanation (IV) -- while loop and until loop of loop statements (additional examples and analysis)

Digital commerce cloud: analyze the design idea of B2B2C multi-user mall system architecture, and open a new era of intelligent mall

Openpnp使用过程的一些问题记录

delegate

3D打印机耗材受潮

Intelligent procurement system solution for processing and manufacturing industry: help enterprises realize integrated and Collaborative Procurement in the whole process

从11小时到25秒--还有优化空间吗?

C WinForm embedded flash

Flutter系列-flutter路由管理

In the first half of the year, there were 7 new unicorns in this field, and the capital scrambled to enter the market

详解openGauss多线程架构启动过程

小甲鱼老师《带你学C带你飞》的后续课程补充