当前位置:网站首页>Efficient supplier management in supply chain

Efficient supplier management in supply chain

2022-06-28 00:25:00 【Data plus cloud link_ Xiaogao】

The clothing industry values Market trends , Fast fashion is even more important . To keep up with the trend , Designers and fashion buyers of many brands , Will keep an eye on the major fashion weeks 、 Popular elements of fashion brand products, etc , Then quickly “ imitation ” shelves , This requires a piece of clothing , From design 、 Production to sales must be completed in the shortest time . The good operation of an enterprise is inseparable from high-quality cooperative suppliers , that , How to efficiently manage suppliers is one of the difficulties for enterprises .

One 、 Under traditional management , The selection of suppliers is one of the difficulties

There are many suppliers in garment enterprises 、 Type miscellaneous . In the traditional management mode , The enterprise evaluation system has been conducted in the form of offline manual evaluation , It not only leads to high operating costs 、 Low efficiency , It is difficult to reflect the real overall situation of the supplier . With the increasingly fierce market competition , Garment enterprises have higher and higher requirements for supplier quality , There is an urgent need to improve the supplier evaluation system and process . for example , They want to achieve automatic sorting of evaluation results , Eliminate and rectify inferior suppliers , And output rectification notice .

In order to be able to integrate 、 Make accurate and objective evaluation on the performance of suppliers comprehensively , Garment enterprises can establish a systematic and comprehensive supplier performance evaluation system , There are several indicators involved here , On time delivery rate 、 Cost margin 、 Product quality qualification rate and satisfaction, etc . Regarding this , Establish a standardized evaluation system for suppliers , On the basis of basic information , Increase the supply capacity of suppliers 、 Ability to perform the contract 、 Multidimensional data such as product quality . By classification , Different templates can be configured , Combine manual scoring with system automatic evaluation , Integrate suppliers 、 An objective assessment . Besides , Supplier scores can be sorted automatically , And the evaluation form can be output .

Two 、 Supplier product quality control is one of the difficulties in quality control .

First, suppliers entering the enterprise organization need to strictly confirm the product technical indicators 、 Production process 、 Test process research and technical requirements agreed by both parties . secondly , At present, many garment groups have relatively decentralized management of their subsidiary suppliers ,('sofastsoft . com') Most of them rely on the personal experience and resources of purchasers to introduce potential suppliers , Different management standards lead to uneven quality of imported suppliers , Bring difficulties to subsequent supplier management .

The supplier management system selects according to the supplier 、 use 、 Education 、 Keep the whole process closed-loop management principle , Promote the classified and detailed management of suppliers in garment enterprises . First , By establishing a unified Supplier Portal , Realize the integrated management of supplier access information , To invite you to register 、 Centralized introduction of suppliers by means of public registration , Use the supplier master data to unify the portal entry method , Reduce the loss of information fragments . When business transactions occur between the supplier and the demander , Full online digital mode based on the system , Between departments of the enterprise 、 Enterprises and suppliers can effectively coordinate applications 、 The examination and approval 、 Place an order 、 deliver goods 、 Quality testing 、 Reconciliation 、 Settlement, etc , And the information of each purchase will also be precipitated in the form of data , So that the follow-up evaluation can be based on , Realize the transparent management of the whole process .

3、 ... and 、 The current accounts between enterprises and suppliers are one of the difficulties .

In financial or internal audit consulting projects , There is a general confusion of current accounts between garment enterprises and suppliers 、 The accounts are not clear . Especially when the business is complex , If there are many installment orders 、 A long time span 、 Frequent orders with the same supplier every month 、 Orders with deposit and quality guarantee deposit, etc , When people change frequently , In particular, accounts cannot be checked 、 Many situations such as overpayment and underpayment . The reason is , Except for the purchase order demand fulfillment defect , The internal control of supplier account management is missing or invalid .

In order to control the risk of accounts receivable of garment enterprises , Enterprises can implement qualification examination procedures for customers and suppliers of subsidiaries , And adopt credit evaluation mechanism for new cooperative customers . Key customers will entrust a third party to issue a credit evaluation report , After approval , Give credit according to the rating ; meanwhile , The company manages and controls according to the risk level of each business , Strictly control high-risk businesses .

Four 、 Supplier procurement closed-loop management is one of the difficulties .

For emerging garment enterprises whose business is in the development stage , Not strong enough in the supply chain , The online rate of suppliers is low . How to make suppliers participate in collaboration at least , Complete settlement transactions efficiently , It is the initial challenge for enterprises .

Through the implementation of the supplier management system , Garment enterprises can not only complete the internal procurement closed-loop management , And build “ Simple settlement ” Pattern , Greatly improve the settlement efficiency . For a large number of paper invoices issued by non online suppliers , Settlement personnel can quickly enter invoices through various import methods . Automatically create invoice settlement documents according to preset rules , Comprehensively improve billing efficiency . For electronic invoice 、 The new trend of paperless , Realize the online invoice management established by purchasers and suppliers . Strong suppliers can complete reconciliation without even logging in to the system , So as to achieve rapid and fair reconciliation in the true sense .

边栏推荐

- Is it safe for Huatai Securities to open an account online?

- 软件工程作业设计(1): [个人项目] 实现一个日志查看页面

- IIC communication protocol for single chip microcomputer

- Mise en œuvre du pool de Threads: les sémaphores peuvent également être considérés comme de petites files d'attente

- [idea] idea formatting code skills

- Promise是什么

- 最新MySQL高级SQL语句大全

- MySQL企业级参数调优实践分享

- Flutter series: Transformers in flutter

- 认识微信小程序项目的基本组成结构

猜你喜欢

Summary of wuenda's machine learning course (14)_ Dimensionality reduction

MySQL分表查询之Merge存储引擎实现

Webserver flow chart -- understand the calling relationship between webserver modules

Technical debt wall: a way to make technical debt visible and negotiable

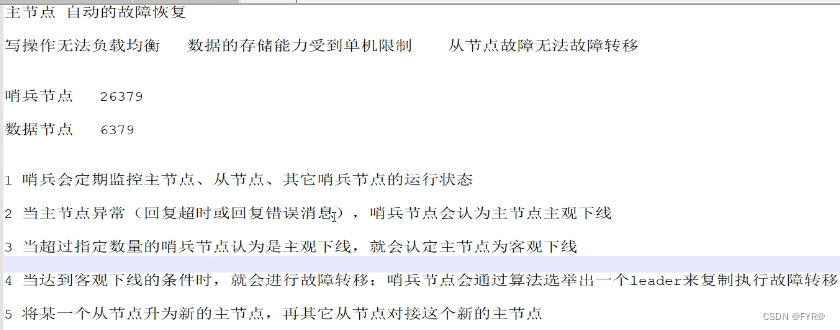

Redis主从复制、哨兵模式、集群的概述与搭建

现代编程语言:zig

什么是cookie,以及v-htm的安全性隐患

吴恩达《机器学习》课程总结(14)_降维

表单form 和 表单元素(input、select、textarea等)

Summary of wuenda's machine learning course (11)_ Support vector machine

随机推荐

zotero文献管理工具安装使用

Character interception triplets of data warehouse: substrb, substr, substring

GFS 分布式文件系统概述与部署

MySQL企业级参数调优实践分享

Request object, response object, session object

Sécurité, économie de carburant et protection de l'environnement chameau

用两个栈实现队列[两次先进后出便是先进先出]

数据仓库入门介绍

线程池实现:信号量也可以理解成小等待队列

Differences and functions between intranet IP and public IP

翻译(5): 技术债务墻:一种让技术债务可见并可协商的方法

Customize MySQL connection pool

一个人可以到几家证券公司开户?开户安全吗

[paper reading | deep reading] sdne:structural deep network embedding

MySQL enterprise parameter tuning practice sharing

MATLB|改进的前推回代法求解低压配电网潮流

内网IP和公网IP的区别及作用

Logging log usage

A summer party

股市小白在网上股票开户安全吗?