当前位置:网站首页>Manufacturing process of PCB 2021-10-11

Manufacturing process of PCB 2021-10-11

2022-06-25 07:43:00 【PCBA chengyaoer】

commonly pcb What are the board making processes ?

- Pcb Production is generally divided into :PCB Layout → Making of core board → Inner layer PCB Layout transfer → Core plate drilling and inspection → Lamination → drill hole → Chemical precipitation of copper on the pore wall → Outer layer PCB Layout transfer → Computer control and copper electroplating . The specific operation process is as follows :

01 PCB Layout (Layout)

- PCB The manufacturer receives from the customer CAD After the document , Because of every CAD Software has its own unique file format , therefore PCB Manufacturers usually send customers CAD File into a unified format ——Extended Gerber RS-274X perhaps Gerber X2. After that, the Engineer shall check PCB Whether the layout conforms to the manufacturing process , Whether there are defects .

02 Making of core board

- Clean the CCL , Prevent the final short circuit or open circuit of the circuit due to dust .

- The picture below is a 8 layer PCB Legend , It's actually made up of 3 Copper clad sheet ( Core plate ) Add 2 Zhang Tongmo , And then it's bound up with a semi-cured sheet . The manufacturing sequence is from the middle core plate (4、5 Floor line ) Start , Keep piling up , Then fix .4 layer PCB The production is similar , It's just 1 Add... To the core plate 2 Zhang Tongmo .

03 Inner layer PCB Layout transfer

- First you have to make the center core (Core) Two layers of lines . After the copper clad plate is cleaned, a photosensitive film will be covered on the surface . This film will cure when exposed to light , A protective film is formed on the copper foil of the copper clad plate . Two layers PCB Layout film and double-layer copper clad plate , Finally, insert the top PCB Layout film , Make sure you have two floors up and down PCB The layout of film lamination is accurate

- It's for the photosensitizer UV The lamp irradiates the sensitive film on the copper foil , Under transparent film , The film is cured , There is still no cured photosensitive film under the opaque film . The copper foil under the curing film is needed PCB Layout lines , Then wash out the uncured photosensitive film with alkali solution , The required copper wire will be covered by a cured photosensitive film . Then use strong alkali , such as NaOH Etch away unwanted copper foil . Tear off the cured film , Show what you need PCB Lay out the circuit copper foil .

04 Core plate drilling and inspection

- After the core board is successfully manufactured, make alignment holes on the core board , It is convenient to align with other materials .

- Once the core board and other layers PCB When pressed together, it can't be modified , So inspection is very important . Automatically and by the machine PCB Compare the layout drawings , Error checking . So the first two layers PCB The board has been made .

05 Lamination

- Here we need a new material called semi curing sheet (Prepreg), It's the core and the core (PCB The layer number >4), And the adhesive between the core plate and the outer copper foil , It also serves as insulation .

- The lower layer of copper foil and two layers of semi-cured sheet have been fixed in advance through the alignment hole and the lower layer of iron plate , Then put the core plate into the alignment hole , Finally, two layers of semi-cured tablets are successively placed 、 A layer of copper foil and a layer of pressure bearing aluminum plate are covered on the core plate . Will be caught in the iron plate PCB The boards are placed on the supports , Then it is sent to the vacuum hot press for lamination . The high temperature in the vacuum hot press can melt the epoxy resin in the semi curing sheet , Fix the core plates and copper foils together under pressure .

- After lamination , Remove the press PCB The upper iron plate of . Then take away the aluminum plate under pressure , Aluminum plate also plays a different role in isolation PCB And guarantee PCB The outer layer of copper foil is smooth . It came out at this time PCB Both sides will be covered with a smooth layer of copper foil

06 drill hole

- First of all, we need to drill through the holes PCB, And then metallize the wall of the hole to conduct electricity .

- Put a layer of aluminum plate on the punching machine , And then PCB Put it on top. . In order to improve efficiency , according to PCB The number of layers will be 1~3 A the same PCB The plates are stacked together to make holes . Last on top PCB Put a layer of aluminum on it , The upper and lower aluminum plates are used for drilling and drilling , It won't tear PCB Copper foil on .

- Next, the operator only needs to select the correct drilling program , The rest is done automatically by the drilling machine . The drill bit of the drilling machine is driven by air pressure , The maximum rotation can reach per minute 15 Wanzhuan , Such a high speed is enough to ensure the smoothness of the hole wall . The replacement of drill bit is also completed automatically by the machine according to the program . The smallest bit can reach 100 Micron diameter , And the diameter of human hair is 150 micron .

- Because in the previous lamination process , The melted epoxy is squeezed to PCB outside , So it needs to be removed . Profiling milling machine according to PCB Correct XY Coordinate to cut its periphery .

07 Chemical precipitation of copper on the pore wall

- The first step is to deposit a layer of conductive material on the hole wall , By chemical deposition throughout PCB The surface of the , It also includes the formation of 1 Micron copper film . The whole process, such as chemical treatment and cleaning, is controlled by the machine .

08 Outer layer PCB Layout transfer

- Outer layer PCB The normal method is adopted for layout transfer , Use positive plate . The outer layer PCB Layout transferred to copper foil , Use photocopied film and photosensitive film to PCB Layout transferred to copper foil .PCB The non line area is covered by the cured photosensitive film . After cleaning the uncured photosensitive film, electroplate . Where there is a film, it cannot be electroplated , And there's no membrane , First copper and then tin . Alkaline etching after film removal , Final tin removal . The circuit pattern is left on the board because it is protected by tin .

- Clean the copper foil on both sides PCB Put it into the film press , The film press presses the photosensitive mold onto the copper foil . The upper and lower layers are photocopied through the positioning hole PCB The layout film is fixed , Put... In the middle PCB plate . And then through UV The illumination of the lamp solidifies the photosensitive film under the transparent film , That is, the lines that need to be reserved . Wash away unwanted 、 After there is no cured photosensitive film , Check it . take PCB Clip in , Electroplate the copper . In order to ensure that the hole position has good enough conductivity , The electroplated copper film on the hole wall must have 25 The thickness of microns , So the whole system will be automatically controlled by computer , To ensure its accuracy .

09 Computer control and copper electroplating

- After the copper film plating is completed , The computer will also be plated with a thin layer of tin . Unload the tin plated PCB Check after the plate , Ensure that the thickness of copper and tin plating is correct .

Next, a complete automatic assembly line completes the etching process .

- First of all, will PCB The cured photosensitive film on the board is washed off . Then wash the unnecessary copper foil covered by it with strong alkali . And then the tin remover will PCB Lay out the tin plating on the copper foil to be removed . After the final cleaning 4 layer PCB The layout is finished .

Want to know more about it , You can pay attention to me !PCB Design -PCB Board making ( Proofing / Batch )-SMT Patch -BOM Orders can be distributed to Jettoban Oh

边栏推荐

- [batch dos-cmd command - summary and summary] - file and directory operation commands (MD, RD, xcopy, dir, CD, set, move, copy, del, type, sort)

- Ltpowercad II and ltpowerplanner III

- 【批处理DOS-CMD命令-汇总和小结】-CMD窗口的设置与操作命令(cd、title、mode、color、pause、chcp、exit)

- Summary of small problems in smartbugs installation

- 栅格地图(occupancy grid map)构建

- Ns32f103c8t6 can perfectly replace stm32f103c8t6

- [leetcode] two num · sum of two numbers

- lebel只想前面有星号,但是不想校验

- FairMOT yolov5s转onnx

- 【批處理DOS-CMD命令-匯總和小結】-cmd擴展命令、擴展功能(cmd /e:on、cmd /e:off)

猜你喜欢

![[batch dos-cmd command - summary and summary] - CMD extended command and function (CMD /e:on, CMD /e:off)](/img/2b/4495a6cd41a2dd4e7a20ee60b398c9.png)

[batch dos-cmd command - summary and summary] - CMD extended command and function (CMD /e:on, CMD /e:off)

Ltpowercad II and ltpowerplanner III

Sichuan earth microelectronics high performance, high integration and low cost isolated 485 transceiver

realsense d455 semantic_ Slam implements semantic octree mapping

![[batch dos-cmd command - summary and summary] - file and directory operation commands (MD, RD, xcopy, dir, CD, set, move, copy, del, type, sort)](/img/fd/1d83ab3b318413ddf70f4e68b28cc3.png)

[batch dos-cmd command - summary and summary] - file and directory operation commands (MD, RD, xcopy, dir, CD, set, move, copy, del, type, sort)

函数模板_类模板

“空间转换”显著提升陡崖点云的地面点提取质量

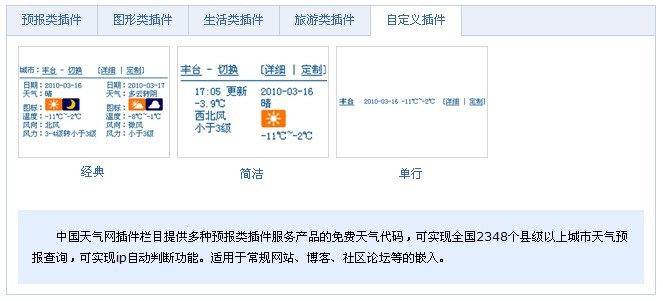

Several good weather plug-ins

GUI pull-down menu of unity3d evil door implementation dropdown design has no duplicate items

Leetcode daily question - 515 Find the maximum value in each tree row

随机推荐

基于激光雷达的林业调查常用术语及含义锦集

CGLIB动态代理

Lebel only wants an asterisk in front of it, but doesn't want to verify it

13 `bs_ duixiang. Tag tag ` get a tag object

[pytest] modify the logo and parameterization in the allure Report

【批处理DOS-CMD命令-汇总和小结】-文件与目录操作命令(md、rd、xcopy、dir、cd、set、move、copy、del、type、sort)

“空间转换”显著提升陡崖点云的地面点提取质量

Runtime——methods成员变量,cache成员变量

Keepalived monitors the process and automatically restarts the service process

用太极拳讲分布式理论,真舒服!

STL tutorial 4- input / output stream and object serialization

稳压二极管的原理,它有什么作用?

【批处理DOS-CMD命令-汇总和小结】-外部命令-cmd下载命令、抓包命令(wget)

诸葛亮 VS 庞统,拿下分布式 Paxos

Harmony food menu interface

用动图讲解分布式 Raft

【蒸馏】PointDistiller: Structured Knowledge DistillationTowards Efficient and Compact 3D Detection

keepalived監控進程,自動重啟服務進程

OAuth 2.0一键登录那些事

函数模板_类模板