当前位置:网站首页>Solutions for safety management and control at the operation site

Solutions for safety management and control at the operation site

2022-06-26 09:16:00 【Merrill Lynch data tempodata】

One 、 Current situation of safety control at the operation site

1、 Risk identification lags behind

The risks at the operation site occur in real time , The existing management and control means are post analysis , The safety risk on site may directly lead to personnel safety accidents .

2、 It is difficult to fully cover the operation control

At present, it is widely used “ Video surveillance + Manual spot check ” The way , Either way, it is difficult to guarantee the on-site control time 、 Full coverage in space .

3、 Risk identification missed detection is high

The monitoring personnel at the operation site need to pay attention to the video , Manual monitoring is easy to miss the key risks in the operation .

4、 High control cost

Take a local distribution network operation site as an example , At least every day 27 At the same time , The annual pure labor cost is as high as several million yuan ; On the basis of one ball per scene , Work 4 It takes about an hour 11.1TB Of traffic , High traffic costs .

Two 、 Solutions for safety management and control at the operation site

For the above problems , Merrill Lynch data around “ whole 、 fast 、 accurate 、 province ” Four key points have built a solution for safety management and control on the job site . Use intelligent means to cover the whole process of the operation site , Through the combination of software and hardware, the recognition is more accurate , Use the new cloud edge collaboration technology to make the discovery of risk problems faster , We are committed to providing all-round security for enterprises , Effectively improve production efficiency .

1、 whole : Intellectualization runs through the whole process of the operation site , Make operation supervision more comprehensive

Cover the mobilization of operation 、 In advance 、 In the matter 、 The whole process after the event , Around people 、 machine 、 material 、 Law 、 All links , Through the operation site 、 Supervise the on-site two-level coordination , Make the supervision on the operation site more comprehensive .

2、 fast : Cloud side collaboration accelerates the discovery of risk problems

Edge computing and model lightweight enabling operation site millisecond computing speed , Achieve faster risk perception ; Zero delay of acoustic photoelectric alarm reminder , Achieve faster risk management .

3、 accurate : The combination of software and hardware makes risk identification more accurate

Depending on the “50+ Artificial intelligence algorithm Model ” And four leading technologies , Ensure that the risk identification on the operation site is more accurate .

4、 province : New technology doubles the value , A lower cost , Enterprises save more money

Rely on edge calculation 、 Service scheduling framework and risk management automation “ SanBanFu ” It saves more money to ensure operation risk control .

3、 ... and 、 Application scenarios of safety management at the operation site

Four 、 Safety control on the operation site The application case

1、 The intelligent analysis of distribution network is realized in a power grid , Save manpower 67%

The local distribution network site of a power grid company is near 30 individual , The environment is complex 、 It's very difficult to supervise . A large number of staff are required to conduct all-weather monitoring in the monitoring room every day , There are high professional requirements for personnel , Unable to achieve full coverage monitoring , It is easy to miss the key risks in the operation . Merrill Lynch data builds a field operation video analysis system based on image recognition and analysis technology , adopt AI The video analysis service interface automatically reviews the on-site operation video , Realize timely feedback of abnormal behaviors , Combined with the business logic, it realizes the specified action recognition based on the business , Full monitoring is realized , Ensure early warning of potential safety hazards , At the same time, it reduces 67% The human cost of .

2、 A distributed intelligent monitoring system is built in a substation , Zero accidents have been realized since the launch

There is a dangerous area in the operation site of a substation 、 Personnel operation is abnormal 、 Improper wearing of safety equipment 、 Low intensity of safety management at the operation site , Operation site management and safety behavior detection only rely on manual methods , Low recognition efficiency , Security risks are difficult to control . Merrill Lynch data builds a distributed intelligent monitoring system based on video monitoring , Realize the real-time monitoring of abnormal behaviors on the operation site , Timely alarm safety risk behaviors , The recognition rate of violations has reached 95%, Effectively reduce the safety risk of substation .

边栏推荐

- Self taught neural network series - 9 convolutional neural network CNN

- Modify coco evaluation index maxdets=[10,15,20]

- Phpcms V9 background article list adds one click push to Baidu function

- 简析ROS计算图级

- ThreadLocal

- Phpcms V9 mobile phone access computer station one-to-one jump to the corresponding mobile phone station page plug-in

- Introduction to common classes on the runtime side

- 关于小程序tabbar不支持传参的处理办法

- Efficiency thesis Reading 1

- 51 single chip microcomputer ROM and ram

猜你喜欢

PD fast magnetization mobile power supply scheme

20220623 getting started with Adobe Illustrator

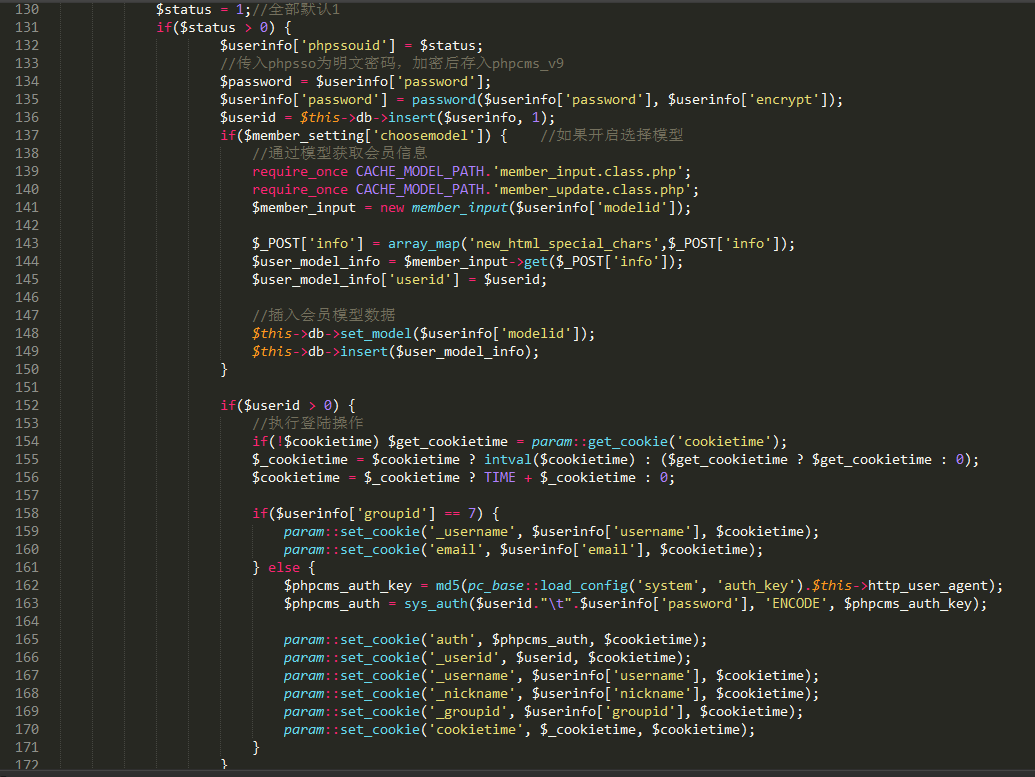

Phpcms V9 remove the phpsso module

《一周学习模电》-电容、三极管、场效应管

20220623 Adobe Illustrator入门

![[300+ continuous sharing of selected interview questions from large manufacturers] column on interview questions of big data operation and maintenance (I)](/img/cf/44b3983dd5d5f7b92d90d918215908.png)

[300+ continuous sharing of selected interview questions from large manufacturers] column on interview questions of big data operation and maintenance (I)

教程1:Hello Behaviac

修复小程序富文本组件不支持video视频封面、autoplay、controls等属性问题

微信小程序如何转换成百度小程序

Regular expression

随机推荐

Cookie session and token

Practice is the fastest way to become a network engineer

《一周搞定模电》-光耦等元器件

Function function of gather()

Games104 Lecture 12 游戏引擎中的粒子和声效系统

Runtimeerror: object has no attribute NMS error record when using detectron2

[program compilation and pretreatment]

Self taught neural network series - 9 convolutional neural network CNN

《一周搞定数电》-逻辑门

Unity webgl publishing cannot run problem

浅谈一下Type-C接口发展历程

Chargement à chaud du fichier XML de l'arbre de comportement

Param in the paper

Vipshop work practice: Jason's deserialization application

行为树 文件说明

如何编译构建

《一周搞定模电》-二极管

Sublime Text3 common plug-ins

[open source] use phenocv weedcam for more intelligent and accurate weed management

Yolov5 advanced camera real-time acquisition and recognition