当前位置:网站首页>Development status of industrial Internet

Development status of industrial Internet

2022-06-24 02:02:00 【yansunxer】

According to the data released by the Ministry of industry and information technology , By the end of this year 8 End of month , Popularization rate of enterprise digital R & D and design tools 、 The numerical control rate of key processes reaches 74.7% and 54.2%, Industrial Internet platforms with certain industry and regional influence exceed 100 home , The total number of connected industrial equipment has reached 7600 Ten thousand units ( set ).

at present , China's industrial Internet application innovation is increasingly active , Not just steel 、 mechanical 、 The power industry , It also infiltrates traffic 、 Energy etc. 40 Key industries , Form a platform design 、 Intelligent Manufacturing 、 Networked collaboration 、 Personalized customization 、 Service extension 、 Digital management and other application modes , Change the production mode and enterprise form of manufacturing industry .

In industrial manufacturing, discrete manufacturing is in the majority . The production process of discrete manufacturing is usually completed by multiple production processes , Such as automobile manufacturing 、 Aviation parts manufacturing, etc . With the acceleration of informatization , The global discrete manufacturing industry is actively moving towards networking 、 The direction of intelligent transformation . However, there are still many bottlenecks restricting the transformation of discrete manufacturing industry , Such as the diverse and heterogeneous protocols between industrial devices 、 Heterogeneity of data types 、 Industrial site “ Information and data islands ”、 There is no interconnection between devices 、 Lack of real-time data collection and processing , These factors have caused great difficulties for the transformation and upgrading of discrete manufacturing industry .

With the rapid development of industrial Internet , These problems are also easily solved . In the process of transformation , Enterprises use advanced and mature digital technology to digitally transform existing products and services or develop intelligent products and services , Accelerate the innovation of enterprise products and services , Explore new market opportunities , Cultivate new business projects , Expand the business model based on digital platform , So as to increase the market share and operating income of the enterprise , Bring performance return to the enterprise . meanwhile , Enterprises rely on the Internet of things 、 Artificial intelligence 、 Big data new and other digital technologies transform and upgrade their operation processes , Build a decision-making system and control system based on data analysis , Improve the accuracy and timeliness of decision-making , So as to reduce the operating cost of the enterprise 、 Improve operational efficiency , Strengthen the advantages of existing core business , Drive the growth of enterprise profits . Then big data analysis can speed up the enterprise decision-making process , Reduce enterprise response time , Improve the overall operation efficiency of the enterprise . In this way, digital enterprises can effectively use consumer data and production data to optimize their production and decision-making process , Improve production efficiency .

At present , The supply chain end of the industrial Internet is still in its infancy , The platform market has been adopted by Alibaba 、 Large scale enterprises like Huawei occupy , But the solution battlefield that really ultimately serves the enterprise , Due to the high degree of customization of enterprise demand , Service geographical distribution 、 And the technical comprehensive ability is required to be high , The market is not yet mature .

边栏推荐

- Embedded hardware development tutorial -- Xilinx vivado HLS case (3)

- Nature Reviews Neuroscience: cognitive and behavioral flexibility - neural mechanisms and clinical considerations

- It's too difficult for me. Ali has had 7 rounds of interviews (5 years of experience and won the offer of P7 post)

- [JS reverse hundred examples] md5+aes encryption analysis of an easy payment password

- SAP mm UB type sto cannot be transferred to vendor consignment inventory?

- [official time limit activity] in November, if you dare to write, you will get a prize

- A multifunctional SSH Remote Server Management Tool

- Clean system cache and free memory under Linux

- Comparison between rule engine and ML model - xlaszlo

- How to build a video website? How much does it cost to build a video website?

猜你喜欢

If there are enumerations in the entity object, the conversion of enumerations can be carried out with @jsonvalue and @enumvalue annotations

layer 3 switch

![[SQL injection 13] referer injection foundation and Practice (based on burpseuite tool and sqli labs less19 target platform)](/img/b5/a8c4bbaf868dd20b7dc9449d2a4378.jpg)

[SQL injection 13] referer injection foundation and Practice (based on burpseuite tool and sqli labs less19 target platform)

Review of AI hotspots this week: the Gan compression method consumes less than 1/9 of the computing power, and the open source generator turns your photos into hand drawn photos

application. Yaml configuring multiple running environments

It's too difficult for me. Ali has had 7 rounds of interviews (5 years of experience and won the offer of P7 post)

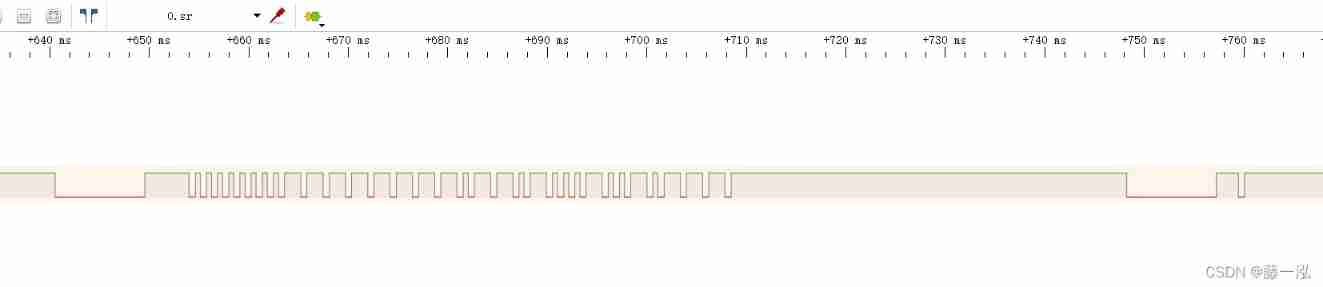

Stm32g474 infrared receiving based on irtim peripherals

Introduction to development model + test model

I, a 27 year old female programmer, feel that life is meaningless, not counting the accumulation fund deposit of 430000

163 mailbox login portal display, enterprise mailbox computer version login portal

随机推荐

Select problem set 3

6、 Symbols and commands for numerical calculation of variables

SQL Server database recovery case analysis

Shopify has quietly taken the second place in e-commerce in North America. Is independent station the "magic weapon" to win?

How to determine whether easycvr local streaming media is started successfully?

[new features] Tencent cloud lightweight ECS will soon support attaching data disks!!!

SAP WM displays the standard report lx09 of TR item

Xmlmap port practice - X12 to CSV

[new function!] How anycast CLB supports multi location & dynamically accelerated load balancing services and high-speed Internet forwarding!

The core battlefield of China US AI arms race: trillion level pre training model

A multifunctional SSH Remote Server Management Tool

Research Report on global and Chinese titanium concentrate market scale and investment prospects 2022-2028

Looking at the future development direction of industrial Internet from the transformation of circulation links of large building materials

Tcapulusdb Jun · industry news collection

What is data analysis? Analysis is not storytelling... - Cassie kozyrkov

Digital case show ‖ made in China for the first time! Tencent cloud tdsql landed in Zhangjiagang bank and worked together to build financial business

Grpc: implement grpc proxy

How to solve the problem of uncaught (in promise) when easywasmlayer plays a video?

OA system module design scheme

Benchmarking Shopify? Similarities and differences between "two giants" of Chinese e-commerce SAAS and Weimeng