当前位置:网站首页>Machine vision: illuminating "intelligence" and creating a new "vision" world

Machine vision: illuminating "intelligence" and creating a new "vision" world

2022-06-26 00:20:00 【Intel edge computing community】

As the first of the five senses , In the information that human beings receive from the outside world 80% It is obtained through vision .

With artificial intelligence 、 The rapid development of edge computing and other emerging technologies , People have also given machines “ know ” and “ reform ” The power of the world , So as to replace the human eye to measure the external environment 、 Identify and judge , Complete the assigned task without contact .

This technology is called machine vision (MV), Known as the “ Eyes of industrial automation ”, It is the most important link to realize intelligent manufacturing .

At the key node of intelligent innovation , The traditional manufacturing industry is facing many transformation challenges .

One side , The cost of manpower is rising , The factory faces “ Recruitment difficulties 、 Difficult to stay at work ” The pressure of the ; On the other hand , Under the wave of Intelligent Manufacturing , The demand for quality inspection and production is increasing , The production line has higher requirements for industrial equipment .

In addition, the country pays more and more attention to the development of intelligent manufacturing , Issued a number of policies and plans to vigorously promote product R & D and market expansion in the field of intelligent manufacturing . stay 《“ the 14th Five-Year Plan ” Digital economy development plan 》 It is clearly put forward in : To 2025 year , The added value of core industries in digital economy accounts for GDP Share to 10%. The manufacturing industry, which is the most important part of the country , The application penetration rate of industrial Internet platform should start from 2020 Year of 14.7%, achieve 45%.

Machine vision quality inspection is an important application scenario of industrial Internet .

At the key node of intelligent innovation , The traditional manufacturing industry is facing many transformation challenges .

One side , The cost of manpower is rising , The factory faces “ Recruitment difficulties 、 Difficult to stay at work ” The pressure of the ; On the other hand , Under the wave of Intelligent Manufacturing , The demand for quality inspection and production is increasing , The production line has higher requirements for industrial equipment .

In addition, the country pays more and more attention to the development of intelligent manufacturing , Issued a number of policies and plans to vigorously promote product R & D and market expansion in the field of intelligent manufacturing . stay 《“ the 14th Five-Year Plan ” Digital economy development plan 》 It is clearly put forward in : To 2025 year , The added value of core industries in digital economy accounts for GDP Share to 10%. The manufacturing industry, which is the most important part of the country , The application penetration rate of industrial Internet platform should start from 2020 Year of 14.7%, achieve 45%.

Machine vision quality inspection is an important application scenario of industrial Internet .

The broad application space breeds sufficient market potential . China is the processing center of the global manufacturing industry , It is becoming one of the most active areas of machine vision in the world .Grand View Research forecast , To 2023 year , The compound growth rate of China's machine vision industry will reach 28%.

In a large number of application scenarios , How does machine vision work ? In what ways can we help the manufacturing industry achieve intelligent upgrading ?

Intel recently released 《 Special issue of machine vision 2022》 The application of machine vision scheme in the actual scene is explained in detail , It also shows how Intel can play an important role “ The empowerer ” role , Join hands with Chinese machine vision industry partners , Help industrial enterprises accelerate their digital transformation 、 Intelligent upgrade .

Intel releases 《 Special issue of machine vision 2022》

What is the “ The eye of wisdom ”?

01 Intelligent quality inspection , Make the field bus more accurate

Machine vision quality inspection is a part of industrial field inspection . In the electronic 、 automobile 、 Metalworking 、 Packaging and other industries , Simple 、 reliable 、 The economical and practical fieldbus technology is becoming more and more popular , Also for process automation 、 Manufacturing automation puts forward higher requirements . therefore , Need to introduce machine vision , Replace the traditional manual detection method .

Machine vision can recognize 、 Extract the key features of the target to be detected , Include dimensions 、 shape 、 Color , At the same time, check whether the product conforms to the design parameters and quality parameters , Once the problem is discovered , Machine vision can also identify the type and location of defects , Assist in production line adjustment .

Although the traditional computer vision technology has been applied in this field , But it is difficult to achieve high accuracy . Machine vision system for industrial environment , It has higher visual perception efficiency and accuracy than human beings , It reduces the possibility of human error , So as to improve the stability of surface defect detection and other applications 、 Accuracy and efficiency .

02 Machine vision , Make the robot softer

With the continuous development of China's economy , Our needs are becoming more and more diverse . Small batch 、 Customization 、 flexible manufacturing , It has become an irreversible trend in China's manufacturing industry .

2020 year , China newly installed 16.8 Ten thousand industrial robots , Of the world's new installations 43.85%. Machine vision can bring “ flexible ”.IDC forecast : Integrating machine vision into robot systems , The operation flexibility can be increased 50%, The quality of the products has been improved 35%.

From logistics 、 Metalworking 、 Car to 3C market , Robots equipped with machine vision , You can grab irregular packages 、 Welding non-standard metal parts 、 Grab randomly placed and stacked components 、 Assemble customized product parts , At the same time, it can also realize navigation and obstacle avoidance , Walk through the manufacturing plants with complex environment with a soft body .

03 Predictive maintenance , Lower production line cost and longer life

To improve production efficiency 、 Reduce operating costs , Factory production lines in many industries are often 24 Hour run , Unplanned sudden downtime often results in heavy losses . here , Rely on sensors to collect key component performance and operator behavior , And analyze it , To achieve predictive maintenance , The manufacturer can more accurately judge when the machine needs to be maintained 、 Optimize production steps .

according to IoTAnalytics Published data : To 2026 year , The predictive maintenance market will continue to maintain high growth , Compound annual growth rate (CAGR) by 31%.

As technology matures , In the past, it can only be used for machine vision and other equipment in high-end fields , It can now be deployed at the edge , Analyze the pictures 、 video 、 Time series and other massive data , And carry out real-time analysis , It can not only improve the yield of the production line , At the same time, it can prolong the service life of the machine , Increase cost effectiveness .

Intel framework

Accelerate machine vision applications

COVID-19 highlights the importance of robots 、 Automation represented by machine vision 、 The important value of intelligent production system —— By applying a machine vision system , Enterprises can reduce the impact of employees' inability to work on the production rhythm and production order , At the same time, reduce the pressure on epidemic prevention and control . And as the epidemic gradually subsided , Manufacturing is expected to accelerate recovery , The market demand for machine vision will also be growing .

A large number of demands have undoubtedly raised the standards and demands of the manufacturing industry for software and hardware technology . In order to speed up the implementation of machine vision in the industrial Internet , Intel offers a range of Hardware 、 Software and toolkits , Help the implementation of more schemes , Accelerate the upgrading of industrial automation industry , Unleash the potential of data at the edge .

At the hardware level , Third generation intel To the strong Scalable processor built-in AI To accelerate the technology , Intergenerational average performance gain 1.46 times , Image classification AI Improved reasoning performance 1.56 times , Provide strong support for the server-side load required by machine vision . Plus Intel Lexus 、 core 、 To the strong Wait for the processor and FPGA And network chips , The processor hierarchy of different computing power levels , At the same time, it has rich expandable high-speed IO And peripheral interface circuit , Can satisfy from the foundation 、 Main stream 、 Advanced and other different machine vision systems .

At the software level , Intel Industrial edge insight platform (EII)、OpenVINO Tool set 、oneAPI tool kit , And the Intel machine vision development suite , The Intel software infrastructure that makes up machine vision :

■ EII It includes a set of mature pre integrated software stacks . Extract at the edge 、 Analyze and store video data and timing data , built-in AI function , Provide... For the edge end AI bonus , Improve operational and productivity .

■ OpenVINO The tool suite aims to accelerate deep learning reasoning , Based on the latest generation of artificial neural network , Scalable across Intel Computer vision and non visual workloads for hardware , And greatly improve performance .

■ oneAPI Toolkit as a cross industry 、 to open up 、 A unified programming model based on standards , Provide a common developer experience across accelerator architectures , It can help the solution development of manufacturing industry achieve faster performance 、 Higher productivity , And broader innovation .

■ Intel Machine vision development kit is a software and hardware tool kit , Based on Intel Lexus 、 core 、 Or Xeon Processor development , Some of them adopt the new generation modular core board hardware architecture — Industrial edge node reference architecture , It can adapt to complex machine vision scenes .

With the blessing of the above software and hardware , Intel offers 3D Visual acceleration scheme , It can provide visual guidance and detection for robots :

Visual guidance : With the help of 3D Visual positioning and recognition of workpiece , Instruct the robot to grasp the workpiece , Used for sorting and stacking 、 Loading and unloading, welding, etc . be based on OpenVINO Intelligent visual guidance and grasping of the tool suite can shorten the reasoning time 6-15 times ,CPU Load reduction 25%-73%.

Visual inspection : Use the workstation camera 、 Laser scanner, etc , Perform contour detection on the workpiece 、 Surface defect detection and 3D reconstruction

Besides , Intel SigOpt AI The training platform can be used to automatically optimize the parameters of the deep learning training pipeline , So as to improve the modeling efficiency , Speed up production .

Of course , These Intel solutions , Not on paper , It has been implemented in many enterprises in all walks of life .

Machine vision makes flowers on the ground

China's intelligent manufacturing has been upgraded by leaps and bounds

In the traditional wheel hub production process , Wheel hubs of different models are often completed manually , Low efficiency , And the training cost is high , It's easy to make mistakes . Made by Xinjie electric AI Hub classification / Segmentation scheme , Use the 11th generation Intel core processor 、OpenVINO Tool kits and oneAPI tool kit , The reasoning accuracy can reach 99%, The reasoning speed ranges from 531 Milliseconds down to 33 millisecond , At the same time, the labor cost will be reduced 75%.

As another manufacturing giant , Foxconn has set up an industrial interconnection factory (Fii), Automation system is widely used , But data congestion and network delay caused by massive data , Prevents device synchronization , Reduce production line efficiency . Foxconn uses the industrial Internet TSN Solution , One of its core objectives is to introduce more AI function , Build an intelligent system to monitor products . Now? , Use 11th generation Intel core processor 、 Intel To the strong And Lingdong processor 、 Intel FPGA Intel Ethernet controller (i210) As a key equipment component ,TSN It can predict and analyze the service life and service condition of the cutting machine , And realize three advantages on the whole :

1, The production line yield in the manufacturing process is improved 8%;

2, The transmission success rate of the industrial Internet of things has increased to 99%

3, Anomaly detection 、 Predictive analysis, etc AI Application improves cost effectiveness and productivity

Besides , In China Telecom 5G MEC Edge cloud platform 、 In the scenarios of junction box positioning welding in the photovoltaic industry , Intel's hardware and software play a decisive role , Help enterprises improve efficiency , Eliminate safety hazards , Reduce operating costs .

Of course , The use of machine vision is not limited to these , It has become an integral part of the intelligent upgrading of infrastructure . With the development of Intelligent Manufacturing , Machine vision as its key element , We will continue to promote the automation of industrial systems 、 Intelligent , Improve the system at cost 、 efficiency 、 Security 、 Stability, etc .

Industrial insight

Wisdom changes the future

Next few years , Manufacturing machine vision systems are expected to integrate more accurate vision sensors , More powerful 、 Diversified computing power , And integrate more powerful machine vision algorithms , Derive more scenario based applications . At the same time, the machine vision system will also be applied in cooperation with industrial robots and other systems , Help build flexibility 、 Intelligent production line , Realizing the vision of intelligent manufacturing .

It is a continuous process to lead the development of machine vision through technological innovation and strategic transformation , Improve the efficiency of the enterprise 、 The stability of the supply chain depends on the quality of the products . Driven by digital innovation technology , More and more manufacturing enterprises will conduct independent research and development 、 Ecological cooperation, etc , Apply machine vision to industrial inspection 、 Industrial robot 、 Predictive maintenance and other scenarios , Transform traditional industrial processes into intelligent processes , It also lays a solid foundation for the mining and utilization of enterprise data resources .

Intel will continue to strengthen and ISV、SI、OEM、ODM And other ecological partners , Provide optimized machine vision solutions , take The end-to-end technological advantages empower partners , Assist in the scene implementation of machine vision solutions , And help more manufacturing enterprises to benefit from these programs , Continue to expand the capability range and service boundary of intelligent manufacturing , Turn massive amounts of industrial data into actionable insights .

边栏推荐

- 安装PSU的时候/usr/bin/ld:warning: -z lazyload ignore

- Tensorrt PB to UF problem

- What do SMT operators do? operating duty?

- Ora-01153: incompatible media recovery activated

- DBCA silent installation and database building

- tensorrt pb转uff问题

- (Reprint) visual explanation of processes and threads

- EBS r12.2.0 to r12.2.6

- 深圳台电:联合国的“沟通”之道

- [advanced ROS] Lecture 1 Introduction to common APIs

猜你喜欢

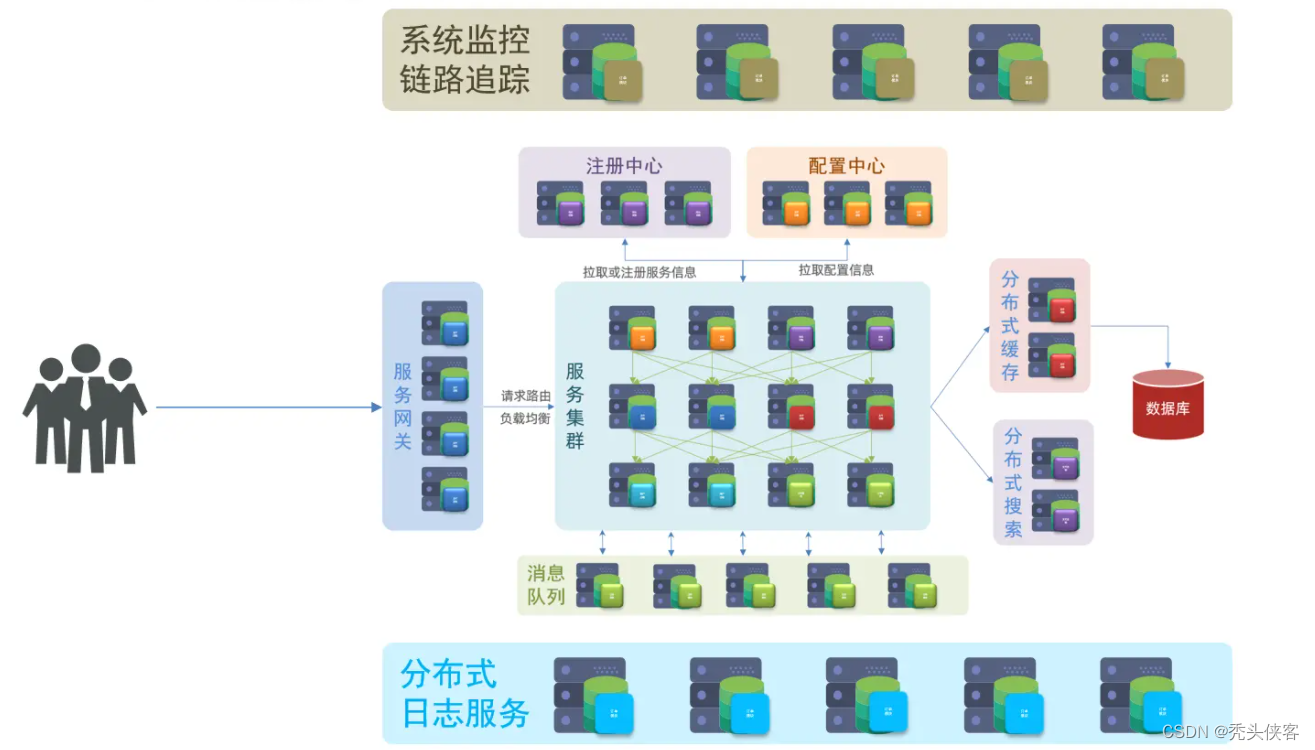

什么是微服务

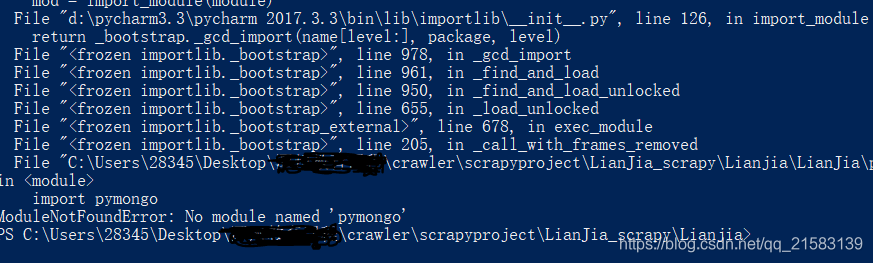

About the solution to prompt modulenotfounderror: no module named'pymongo 'when running the scratch project

元宇宙中的法律与自我监管

Thrift入门学习

Ora-01153: incompatible media recovery activated

Redis memory elimination mechanism

渲云携手英特尔,共创云渲染“芯”时代

Notes on the method of passing items from the spider file to the pipeline in the case of a scratch crawler

My blog is 2 years old and 167 days old today. I received the pioneer blogger Badge_ Old bear passing by_ Sina blog

After being trapped by the sequelae of the new crown for 15 months, Stanford Xueba was forced to miss the graduation ceremony. Now he still needs to stay in bed for 16 hours every day: I should have e

随机推荐

POSTMAN测试出现SSL无响应

《SQL优化核心思想》

10.4.1、數據中臺

10.2.2、Kylin_kylin的安装,上传解压,验证环境变量,启动,访问

Use Coe_ load_ sql_ profile. SQL fixed execution plan

(Reprint) visual explanation of processes and threads

14.1.1、Promethues监控,四种数据类型metrics,Pushgateway

Simulink求解器综合介绍

如何绕过SSL验证

SPI锡膏检查机的作用及原理

ValueError: color kwarg must have one color per data set. 9 data sets and 1 colors were provided

ORA-01153 :激活了不兼容的介质恢复

SMT Mounter workflow

11.1.2、flink概述_Wordcount案例

Frequently asked questions about redis

redis之集群

Mysql5.7.31自定义安装详细说明

把控元宇宙产业的发展脉络

Maintenance and key points of SMT Mounter

被新冠后遗症困住15个月后,斯坦福学霸被迫缺席毕业典礼,现仍需每天卧床16小时:我本该享受20岁的人生啊...